ADAM is About Advanced Design and

Manufacturing and Cyberspace Product and Service Reviews in our

Virtual Exhibition Hall, Including the Latest News, the Most

Innovative International Products & Services, New Strategies,

R&D, and more...

ADAM: R&D

Article

Flaherty, M., Ranky,

Paul G., Ranky,

Mick F., Sands, S., Stratful, S.: An

Engineering Multimedia Approach to Servo Pneumatic

Positioning

Published by ADAM at

http://www.cimwareukandusa.com, © Copyright by CIMware Ltd. UK

and CIMware USA, Inc.

Please feel free to download this paper with

its full contents,

FREE

of charge, but always mention the website:

http://www.cimwareukandusa.com and the author(s) as the

source!

Website:

http://www.cimwareukandusa.com

Email: cimware@cimwareukandusa.com

Go to Welcome Page

Go to ADAM

Contact Addresses: Dr M. Flaherty,

Mr. S. Sands and Mr. S. Stratful can be contacted at: FESTO (UK)

Limited, Automation House, Harvest Crescent, Ancells Business Park,

Fleet, Hampshire, GU13 8XP, United Kingdom, or via ADAM by

email: cimware@cimwareukandusa.com

Mick F Ranky can be contacted at CIMware by

email: cimware@cimwareukandusa.com

Paul G. Ranky can be contacted at

ADAM

or at NJIT, USA, Department of Industrial and Manufacturing

Engineering, New Jersey Institute of Technology, NJ 07102, USA,

Email: ranky@admin.njit.edu

Contents

Abstract

Go to top

Servo pneumatics retains the advantages of standard pneumatics and

adds the opportunity for closed loop controlled, programmable

positioning to within fractions of a millimeter in systems in which

positions can be approached rapidly and without overshoot, stability

under variable loads and conditions, and adaptive control for

optimized positioning.

Our challenge was to create an interactive multimedia program that

could communicate exciting technical material to interested parties,

including students and academia, professional design, industrial and

manufacturing systems engineers, marketing and sales engineers and

managers in a non-linear, enjoyable fashion. Our approach was that of

interactive multimedia on CD-ROM, allowing the integration of text,

color images, videos and animation for the purpose of following an

engineering problem solving approach, both when modeling, as well as

when illustrating real-world solutions with interactive digital

videos.

Furthermore, this article introduces Outcome - Driven Assessment

principles (as defined by ABET - The American Accreditation Board of

Engineering Education), as the key to our educational multimedia

design objectives. It illustrates open loop controlled pneumatic and

closed loop-controlled servo pneumatic positioning systems, their

components, their programming and some of their applications.

Keywords

Engineering education, Interactive multimedia education, Pneumatic

positioning and control, Servo pneumatics control, Programming and

applications of servo pneumatic systems, Outcome - Driven Assessment,

ABET (American Accreditation Board of Engineering and Technology)

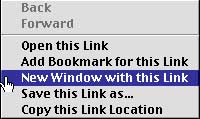

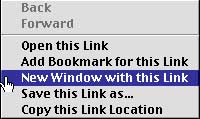

As a general idea let us suggest that when you

look up the selected website you choose "New Window with this

Link..." in your browser by clicking with the right-hand-side

mouse button (PC) or by keeping the mouse button pressed down (on the

Mac) immediately after you have clicked on the hyperlink. This way

when you wish to "hop back" to the www.cimwareukandusa.com site you

can do it in one step!

An introduction

to our educational objectives with a strong emphasis on Outcome

Driven Assessment

Go to top

In terms of our educational design and development goals we have

followed the principles of Outcome - Driven Assessment and created an

interactive educational package that is compatible with many of the

requirements set by The American Accreditation Board of Engineering

and Technology (ABET).

In order to gain an insight into what these Outcome - Driven

Assessment Principles are, and how we have followed them with our

interactive engineering multimedia design

let us first outline the philosophy and the requirements that relate

to our educational multimedia development, and then give a list (with

examples) of the way our interactive multimedia design supports these

educational principles and requirements ([1] to

[4]).

As stated by ABET, The Accreditation Board for Engineering and

Technology is recognized in the United States as the sole agency

responsible for accreditation of educational programs leading to

degrees in engineering. The first statement of the Engineers' Council

for Professional Development (ECPD, now ABET) relating to

accreditation of engineering educational programs was proposed by the

Committee on Engineering Schools and approved by the Council in

1933.

The original statement, with subsequent amendments, was the basis

for accreditation until 2000. (Kindly note, that he statement

partially presented here is required of engineering programs

beginning in 2001 in the USA).

Similarly to the various European Engineering Accreditation

Systems, the USA/ ABET accreditation process is a voluntary system of

accreditation that

- Assures that graduates of an accredited program are prepared

adequately to enter and continue the practice of engineering

- Stimulates the improvement of engineering education

- Encourages new and innovative approaches to engineering

education, and

- Identifies these engineering education programs to the

public.

According to ABET, engineering programs must demonstrate that

their graduates have

- an ability to apply knowledge of mathematics, science, and

engineering

- an ability to design and conduct experiments, as well as to

analyze and interpret data

- an ability to design a system, component, or process to meet

desired needs

- an ability to function in multi-disciplinary teams

- an ability to identify, formulate, and solve engineering

problems

- an understanding of professional and ethical

responsibility

- an ability to communicate effectively

- the broad education necessary to understand the impact of

engineering solutions in a global and societal context

- a recognition of the need for, and an ability to engage in

life-long learning

- a knowledge of contemporary issues

- an ability to use the techniques, skills, and modern

engineering tools necessary for engineering practice.

Furthermore, ABET clearly states, that each engineering program

must have an assessment process with documented results, in which

evidence must be given that the results are applied to the further

development and improvement of the program.

The assessment process must demonstrate that the outcomes

important to the mission of the institution and the objectives of the

program, including those listed above, are being measured.

The ABET

Professional Component requirements and their satisfaction by means

of interactive multimedia design

Go to top

In terms of important criterion, that had a major effect on our

engineering multimedia design, let us discuss in more detail what

ABET refers to as the "Professional Component". The Professional

Component requirements specify subject areas appropriate to

engineering but do not prescribe specific courses.

Amongst others, it states, that the engineering faculty must

assure that the program curriculum devotes adequate attention and

time to each component, consistent with the objectives of the program

and institution. Students must be prepared for engineering practice

through the curriculum culminating in a major design experience based

on the knowledge and skills acquired in earlier coursework and

incorporating engineering standards and realistic constraints that

include most of the following considerations: economic;

environmental; sustainability; manufacturability; ethical; health and

safety; social; and political.

To summarize, according to ABET, the professional component

must include the following:

- One year of a combination of college level mathematics and

basic sciences (some with experimental experience) appropriate to

the discipline

- One and one-half years of engineering topics, to include

engineering sciences and engineering design appropriate to the

student's field of study

- A general education component that complements the technical

content of the curriculum and is consistent with the program and

institution objectives.

In terms of facilities, ABET states and implies, that classrooms,

laboratories, and associated equipment must be adequate to accomplish

the program objectives and provide an atmosphere conducive to

learning.

Appropriate facilities must be available to foster faculty-student

interaction and to create a climate that encourages professional

development and professional activities. Programs must provide

opportunities for students to learn the use of modern engineering

tools. Computing and information infrastructures (including

multimedia and the Internet) must be in place to support the

scholarly activities of the students and faculty and the educational

objectives of the institution.

Following the ABET requirements and the principles of Outcome -

Driven Assessment in our educational multimedia design, the issue was

to be able to structure and story-board the several hundred photos,

over 50 minutes of interactive, digital videos, animation and text on

the CD-ROM in such a way that the final educational package satisfied

the following criteria:

- Engineering science principles should be introduced and

discussed in a simple, easily graspable way using modeling,

animation as well as real-world

systems and examples.

- The program could be viewed both in a sequential way (i.e.

following our programmed path, from the introduction to the end),

as well as in a non-linear (or in other words direct access

fashion) following a "multimedia talking book" format, using

literally any multimedia PC or Mac.

- Data/ information could be found quickly and easily even for

any non-linear navigator either by just clicking with the mouse

and interrogating various screens, or by going through the index

and navigating back-and- forth between the integrated material and

the index entries.

- The CD-ROM should employ fast object linking methods, both

when running it as an integrated program, as well as when

accessing individual objects, such as individual images, videos,

or animation.

As examples, consider that in our CD-ROM we have included an

explanation to the way pneumatic components can be used for building

various engineering systems, the way such systems are integrated

by means of open-loop and/ or closed loop control by means of PLCs,

we have covered some of the most important aspects of their

programming, the way multi-disciplinary teams should assess such

system developments covering the economic as well as technical

aspects, the way such components and systems

are applied in industry, touching

on the engineering problem solving and design experience, and others,

such as the assembly, commissioning and maintenance aspects of such

systems ([5] to [8]).

To summarize the above in a more systematic way, we have

attempted to fulfill the following educational goals and requirements

for our learners (i.e. for "the student"):

- Have the choice and the freedom to learn

- Be supported by the multimedia based learning materials and

technology and that

- Offer the best use of learning objectives, in a user-friendly

style, environment and flexibility (time, place and pace)

- Enable tutor marked assignments, and/or self-assessment

- Provide an education process and experience that, as far as

possible, is designed and delivered to satisfy individual needs

while being controlled by the individuals themselves

In this context, the benefits of using interactive multimedia

to the learners/ users include the following ([9] and

[10]):

- Multimedia is inexpensive. Literally all new PCs and Macs are

powerful multimedia machines with, CD-ROM, video, sound and

networking capabilities (including the Internet)

- Students can study at their own time, place and pace

- In the case of CD-ROMs learning is conducted in a non-linear

(or in other words direct access) fashion, compared to the

traditional linear mode of delivery. This enables learners to

learn by exploring versus learn as told!

- The entire learning process becomes more student versus

lecture centered

- Multimedia is easy to use and is interactive. Most programs

are "hot-spot" driven, enabling the user to move the cursor on the

screen with the mouse and interrogate new areas of information by

clicking on the selected object

- The "explore & act" nature of the learning process

satisfies the young generation's appetite for learning at their

own pace and sequence, under their own control

- Students can have as many goes at solving a problem, or

exploring an idea, taking as much time as desired or is

available

- Mistakes made can be corrected without penalties

- Multimedia tools, or a subset of such technology and a variety

of media is available during the learning process

- Self-assessment is possible. This means that students become

more self-critical, they participate directly in their own

learning process, it eliminates "hidden curriculum" and

self-assessment questions give instant assessment and

response

- Tutorial support is available if required. In the case of an

up-to-date learning program on-line help is available on the

Internet. This means, that the relatively fast CD-ROM technology

(typically 12x =1800 to 24x = 3600 Kbytes/sec transfer rates)

offers the bulk of the material using the CD-ROM as a mass storage

media (650 Mbytes, max.) and the Internet (a relatively slow

technology with relatively slow transfer rates; typically 1.8

Kbytes/sec (14.4 modem) to 16 Kbytes/sec (ISDN)) supports

real-time learning needs, or very frequently changing

information

- When using multimedia learning tools, students are better

motivated, because they can learn by exploring versus being

told

- With multimedia the entire education process is more suited to

satisfy individual needs and small-team oriented activities

because it can both satisfy synchronous as well as asynchronous

collaboration between team members, even if the teams are apart

physically

- Interactive multimedia supports the concept of "telepresence",

meaning, that despite the fact that the learner(s) and the

tutor(s) are physically apart, they are electronically linked by

sharing the same material they are exploring on CD-ROMs and the

Internet. Furthermore, this means, that the "telepresence"-type of

collaboration supports both performance as well as learning

- Groups (i.e. small teams) can solve more interesting and more

complex problems than can an individual working alone. This is

most effective if all members of the team can "speak the same

language" - meaning that they are brought up to the same level of

understanding of the basics related to the particular area.

Interactive Multimedia can do an excellent job in supporting this

process effectively and at a low cost

Last but not least, there is an other very important issue: since

failure is not exposed in Open/ Distance Learning situations, fear is

not part of the learning and testing process. Multimedia supports

student performance.

Student motivation can quickly diminish if students aren't

confident that they can solve authentic problems. The learning

process, for all parties involved, is the most successful if students

have the opportunity to succeed ([11] to [16]).

Following the above outlined principles, according to our

experiences in classrooms, laboratories, and associated facilities

interactive multimedia fosters faculty-student interaction and

creates a climate that encourages professional development and

professional activities.

Such educational programs, preferably coupled with real-life

experiments, provide opportunities for students to learn the use

of modern engineering tools, including computing and information

infrastructures.

Introduction to

standard pneumatic positioning solutions and the instability of open

loop pneumatic systems

Go to top

In order to introduce and discuss engineering science principles

in a simple, easily graspable way using modeling, animation as well

as real-world systems and examples, we have chosen open-loop as well

as closed loop controlled pneumatics.

In industry, pneumatics is selected for automation and handling

tasks as a preferred medium because it is relatively inexpensive,

simple to install and maintain, offers robust design and operation,

is available in a wide range of standard sizes and design

alternatives and offers high operating speeds and cycle rates.

Positioning with standard pneumatics is possible but with

limitations. One of the limitations of compressed air as a

positioning medium is the difficulty of obtaining movement other than

those of a binary type: In/ Out, Retracted/ Extended, Raised/

Lowered, etc.

Movements are usually obtained from a double acting pneumatic

cylinder actuated by a five port, two position (5/2) valve. Stroke

movements are made along the full length of the cylinder.

Furthermore, open loop pneumatic systems are not stable, because

the stop position depends upon external variables, such as the speed

of the cylinder, the mass being moved, the external forces acting on

the system, the system pressure, the leakage across the piston, the

valves, or fittings and to a lesser extent, the repeatability of

response within the PLC (Programmable Logic Controller) and the

repeatability of the response of the valve.

Servo pneumatics retains the advantages of standard pneumatics and

adds the opportunity for closed loop controlled, programmable

positioning to within fractions of a millimeter in systems in which

positions can be approached rapidly and without overshoot, stability

under variable loads and conditions, and adaptive control for

optimized positioning.

In open loop pneumatic systems the stop position depends upon

external variables, such as the speed of the cylinder, the mass being

moved, the external forces acting on the system, the system pressure,

the leakage across the piston, valves, or fittings and to a lesser

extent, the repeatability of response within the PLC and the

repeatability of the response of the valve.

Several of these factors vary in most industrial applications

therefore in most cases the stopped mid stroke position of a

pneumatic actuator is not accurate, repeatable or stable. As an

example consider a vertically mounted cylinder in a stop position,

with and without an external load. The air in the cylinder is

compressible, therefore the load force causes the lower chamber in

the cylinder to be further compressed, while the upper chamber

expands.

In order to explain the simplest possible open loop controlled

pneumatic system we have created an interactive

animation sequence on digital video. The animation shows the

control sequence using a standard configuration.

The fact, that the animation is interactive, meaning it can be

controlled frame-by-frame, standard speed play, and fast forward (and

all above in reverse) functions, enables the learner, or user to

analyze the most important transition points in the entire sequence.

This animated model, coupled with a real-world interactive digital

video example provides the engineering experience on how such systems

work.

An overview

of servo pneumatic components & systems with particular interest

towards comparing it with standard, open loop controlled pneumatic

positioning solutions

Go to top

Servopneumatics is an electro-pneumatic solution to accurate and

fast positioning. It is an alternative to "electric only"

positioning, since it eliminates electric motors with their

relatively expensive maintenance procedures and power supplies, as

well as offers the often crucial "clean air, zero sparks" solution to

positioning.

Note, that in the digital, interactive video put on this screen,

the economic aspects of this new technology are discussed. From an

educational point of view, this was very important to illustrate that

a professional designer will consider and then chose a new

technological solution on the basis of not just technical, but also

other merits, including cost.

Servo pneumatic actuators use proportional pneumatic valves and

rely on the integration of electronic, closed- loop controlled servo

techniques. The heart of the system is the axis controller, that

continuously processes motion information in the form of positioning

control signals, as well as fulfills diagnostic and other

functions.

The positioning control signals are sent to the servopneumatic

valve, where they are converted to a flow output, proportional to the

input signal. This output is fed to the pneumatic actuator, which

moves to the pre-programmed (i.e. "to be") stop position.

The actual position (i.e. "as is") is read by the position

transducer (a sensor), and a signal is fed to the controller for

comparison with the programmed position. If there is a difference

(i.e. error) in the actual (i.e. "as is") position, the axis

controller sends a correction signal to the valve and the movement is

executed - in a similar fashion to a closed loop a numerically

controlled, CNC system.

There are four main components within the FESTO Servo Pneumatic

Positioning System. These being:

1. Actuator

2. Measuring device

3. Servo (Dynamic Control) valve

4. Controller

In order to provide a comprehensive overview to both the academic

as well as the professional engineering community, in the CD-ROM, we

classify and discuss the main servo-pneumatic components as

follows:

- Types of standard actuators for use with servo pneumatics

- Standard

- Rodless cylinders

- Types of measuring devices

- Analogue potentiometer

- Digital Temposonic

- Integrated Temposonic

- Valves

- Servo (Dynamic Control) valve

- Function & characteristics

- Controllers & Interfaces

- Selection & sizing of components for optimum system

performance

- Advantages of Servo Pneumatic Control

Let us give some examples of the above, with particular interest

towards the educational challenges on how we have communicated the

information to the learners/ users of our system. Note, that in order

to illustrate our educational and multimedia design solutions, we are

discussing this topic in the Figures attached to this paper. These

are actual screen shots taken from the

CD-ROM itself. (Note, that the original screens are in full color,

and that the images are digitized in thousands of colors, offering

clear colors and edges. In this Internet-based article we have

reduced the resolution and the number of colours to support typical

transfer rates over the net).

The assembly of a

servo system: Testing the assembly - a preparation for recognizing

the way systems can be integrated

Go to top

When assembling servopneumatic systems the engineer/ technician

must follow strict technical instructions and guidelines - as listed

below.

In order to explain these instructions in detail as well as to

make sure, that all important principles and techniques are well

understood, we have included several interactive

digital videos into the CD-ROM that can be studied in detail,

played even frame-by frame - if necessary. (One should note, that

such visually attractive problems as the assembly of complex systems

lends itself to interactive multimedia education).

- The critical technical instructions we had to communicate in

our educational program are as follows:

- All mechanical assemblies are complete and checked to ensure

free running throughout their stroke length

- Electrical connections can then be completed

- The wiring connections must be made to the sensor, the valve

and the power supply

- A battery to back-up RAM program memory must be attached to

the controller and connected to the pin strips

- Certain inputs are also required to allow the controller to

pass beyond the initialization stage. These depend upon the

selected mode of operation required. Once all connections have

been made it is possible to check the controller status, the valve

connections / operation, and the sensor connections /

operation.

- Pneumatic supply pressure should be slowly "bled" in to the

system after ensuring that all areas are safe, that there are no

loose components, all parts have unrestricted movement, no

personnel can be hurt and machinery or parts damaged

- When using mechanically coupled rodless cylinders the sealing

strip should be orientated downwards to prevent the ingress of

dust or liquids

- Standard cylinders should be guided to ensure relatively

constant friction throughout their stroke length

- Ensure that the measuring device is correctly set or protected

from bearing the force of the actuator in the event of an

accident

- External shock absorbers and end of stroke stops are

recommended where a sensor has been selected shorter then the

cylinder stroke length.

- Fit the servo valve as close as possible to the

actuator

- The air supply should be dry and unlubricated

- A maximum size 5-micron filter should be fitted in the air

supply line

- Use a large bore tubing run to the servo valve - with a

minimum bore greater or equal to the nominal bore of the servo

valve

- Straight fittings and matched pipe runs enhance system

performance

- Where the air supply fluctuates an in-line air reservoir

smoothes out variations and again enhances system performance

- Consideration should be given to the required actions under

emergency stop or air dump / failure conditions

- Standard circuits are available in the event of an emergency

stop to:

- De-pressurize the cylinder

- Clamp the piston by trapping the air on both sides

- Pressurize either side of the piston thus causing the

cylinder to go to a 'safe' position - left, right, up or

down.

- The servo valve has a very high flow and switching rates. This

causes it to be noisy unless silencers are used. It is recommended

that a re-classifier or exhaust air reservoir manifold is used.

These allow the exhausting air a very free flow path at the same

time as significantly dropping the exhaust air velocity.

The

importance of detail at component level

Go to top

In order to increase the awarenes of our engineering students,

and/or maintenance engineers of the importance of detail at component

level, specifically regarding the electrical connection, we had to

emphasize the following:

- If the cylinder body is mounted to the machine and the rod or

carriage moves the valve port nearest solenoid head (port-2)

connects to 'zero or home end' of cylinder. (The electrical

connection of the measuring device is at the same end of

cylinder)

- If the cylinder body moves and the rod or carriage is mounted

to the machine frame the valve port furthest from the solenoid

head (port-4) connects to 'zero or home end' of cylinder. (The

electrical connection of the measuring device is at the same end

of cylinder)

- Connecting cables can be cut to length before assembling to

the screw in terminals. All connections should be checked to

ensure good electrical continuity.

- Screened cables are required in control systems handling

analogue signals. Therefore the servo valve cable and the

potentiometer cable are screened. In noisy electrical environments

it is particularly important that these are terminated on the

spade connections provided at the rear of the axis controller to

prevent interference.

- There is an impedance balancing device incorporated in the

cable near the plug on the potentiometer system. This should not

be tampered with, the cable should be reduced in length from the

free end.

In terms of following our educational design and development goals

based on the principles of Outcome - Driven Assessment, in this

section students have to face real-life problem solving situations

and with the aid of multimedia, immediately get answers to

illustrated problems ([17] to [21]).

Summary and

conclusions

Go to top

In order to increase the ability to apply knowledge of

mathematics, science, and engineering, to design and conduct

experiments, as well as to analyze and interpret data, to design a

system, component, or process to meet desired needs, to work in

multi-disciplinary teams, to identify, formulate, and solve

engineering problems, to understand the impact of engineering

solutions in a global and societal context, and to use the

techniques, skills, and modern engineering tools necessary for

engineering practice we have developed the "Introduction to Servo

Pneumatic Positioning" interactive multimedia program.

The combined results of various independent surveys conducted by

the FESTO Forum members in the UK, the University of Abertay Dundee

(Scotland), by the University of East London (England), and by NJIT

(New Jersey Institute of Technology, USA) support the discussed

benefits of multimedia and open learning in general.

Based on the responses, it is obvious that both students as well

as academics have rated interactive multimedia to be on the top of

the list of advanced learning tools, in comparison to traditional

methods, such as wall charts, the black-board, the white board,

overheads, and others.

Interactive multimedia is not against able faculty. On the

contrary, it supports both students as well as the faculty that

teaches a particular course.

As amongst others, ABET puts the importance of faculty the

following way: the faculty is the heart of any educational program.

The faculty must be of sufficient number and must have the

competencies to cover all of the curricular areas of the program.

There must be sufficient faculty to accommodate adequate levels of

student-faculty interaction, student advising and counseling,

university service activities, professional development, and

interactions with industrial and professional practitioners, as well

as employers of students.

The faculty must have sufficient qualifications and must ensure

the proper guidance of the program and its evaluation and

development. The overall competence of the faculty may be judged by

such factors as education, diversity of backgrounds, engineering

experience, teaching experience, ability to communicate, enthusiasm

for developing more effective programs, level of scholarship,

participation in professional societies, and registration as

Professional Engineers.

Educating others as well as ourselves is not a simple task. Since

each of us is unique, it is necessary to find out more about us as

well as about the "art and science" based methods, tools and

technologies that relate to modern education. Open/ Distance

Learning, Open/ Distance Access Flexible Learning, Distance Learning

and Interactive Multimedia represent some of these methods, tools and

technologies.

The world is moving away from rigid mass production systems,

because industry has discovered that customers want different

products that satisfy their individual or small group needs and not,

as in the past necessarily those of the accountants, managers,

designer, or manufacturer, therefore it is strategically important to

renovate the pedagogical methods and environment in the educational

institutions and stimulate the diffusion of good multimedia- based

lifelong educational practices and solutions.

Acknowledgments

We hereby would like to express our thanks to FESTO, NSF (The

National Science Foundation, USA), NJIT (New Jersey Institute of

Technology, Newark, USA), ABET in the USA, The National Council for

Educational Technology (NCET, UK), and The University of East London

(UK) for their support in our multimedia developments.

References and Further

Reading

Go to top

[1] Ranky, P. G, Ranky, M. F, Flaherty, M, Sands, S and

Stratful, S: FESTO: Servo Pneumatic

Positioning, an Interactive Multimedia CD-ROM with Internet

support. Over 330 interactive screens, 650 Mbytes, CIMware &

FESTO Automation joint development 1996, 1998, Interactive Multimedia

Design & Programming by Ranky P G and Ranky M F. Internet Web

site: www.cimwareukandusa.com

[2] Servo Pneumatic Positioning & Control Programming

Manuals, by FESTO, 1996, 1998.

[3] ABET documents and Correspondence on Outcome - Driven

Assessment, ABET 2000. The Accreditation Board of Engineering and

Technology, USA, 1996.

[4] Ranky, P G: Interactive Multimedia for Engineering

Education, European Journal of Engineering Education, Vol. 21, No. 3,

1996, p.273-293.

[5] Ranky, P G: An Introduction

to Concurrent Engineering, an Interactive Multimedia CD-ROM with

off-line and on-line Internet support, over 700 interactive screens

following an Interactive Multimedia Talking Book format, CIMware

1996, Interactive Multimedia Design & Programming by Ranky, P G

and Ranky, M F. Web site: www.cimwareukandusa.com

[6] Ranky, P G: An

Introduction to Computer Networks, an Interactive Multimedia

CD-ROM with off-line and on-line Internet support, over 700

interactive screens following an Interactive Multimedia Talking Book

format, CIMware 1996, Interactive Multimedia Design & Programming

by Ranky, P G and Ranky, M F. Web site: www.cimwareukandusa.com

[7] Ranky, P G: An

Introduction to Flexible Manufacturing, Automation &

Assembly, an Interactive Multimedia CD-ROM with off-line and

on-line Internet support, over 700 interactive screens following an

Interactive Multimedia Talking Book format, CIMware 1996, Interactive

Multimedia Design & Programming by Ranky, P G and Ranky, M F. Web

site: www.cimwareukandusa.com

[8] Ranky, P G: An

Introduction to Total Quality (including ISO9001), an Interactive

Multimedia CD-ROM with off-line and on-line Internet support, over

700 interactive screens following an Interactive Multimedia Talking

Book format, CIMware 1997, Interactive Multimedia Design &

Programming by Ranky, P G and Ranky, M F. Web site:

www.cimwareukandusa.com

[9] Mager, Robert F.: Preparing Instructional Objectives,

Kogan Page 1992

[10] Kayfetz, Janet L. and Stice, Randy L.: Academically

speaking, Wadsworth, Boston, 1987

[11] Ranky, P G: Flexible manufacturing cells and systems

in CIM, Book/CD combo, CIMware

Ltd., 1990, 1998. 233 pp. and the CD-ROM with over 700 interactive

screens

[12] Ranky P G: A methodology for supporting the product

innovation process, USA/Japan International IEEE Conference on

Factory Automation, Kobe, Japan, 1994. p. 234-239

[13] Norman, D.A and Spohner, J.C: Learner-centered

Education, Communications of the ACM, April 1996/ Vol. 39. No.4,

p.24-27.

[14] Shipley, T A and Armacost, R L: Systematic approach

to new product development, Computers and Industrial Engineering, Sep

1993 25(9) 333-336p

[15] Bessant, J: The lessons of failure: learning to

manage new manufacturing technology, Int Jnl Technology Management,

1993 8(3/4/5) 197-215p

[16] McCahon, C S, Rys, M J and Ward, K H: The Impact of

Training Technique on the Difficulty of Quality Improvement Solving,

Industrial Management & Data Systems, 1996 96(7) 24-31

[17] Senker, P: The Development and Implementation of

National Vocational Qualifications: An Engineering Case Study, New

Technology, Work & Employment, 1996 11(2) 83-95

[18] Forbes, D A and Spence, J: An Experiment in

Assessment for a Large Group, Innovative Teaching in Engineering

(Sheffield, Horwood), 1991.

[19] Mannison, M, Patton, W and Lemon, G: Interactive

Teaching Goes to University: Keeping Studenyts Awake and Learning

Alive, Higher Education Research and Development, 1994, Vol. 13, pp

35-47.

[20] Murray, R and Brightman, J R: Interactive Teaching,

European Journal of Engineering Education, Vol. 21, No. 3, 1996,

p.295-308.

[21] Somers, C B: Correlates of Engineering Freshman

Academic Performance, European Journal of Engineering Education, Vol.

21, No. 3, 1996, p.317- 327.

Go to top