Web-based Video Workbook

for

FMS Video Programs Vol. 9 & 10,

on Video Tapes 9 & 10 or on Digital Video CD

by

Written and presented by Dr. Paul G. Ranky and Industrial Contributors, including Mr. Robin Truman (GPT-GEC Plessey Telecommunications Ltd), Mr. Michael J. Legg and Mr. Alan M. Rines (Hitachi Seiki UK Ltd.), Dr. Allan Parker (Lucas Engineering & Systems Ltd), Mr. Roland Thomas and Mr. Wim Onink (ERT Ltd), Mr. Les Pratt (Yamazaki Machinery UK Ltd), Mr. Geoff Harrington (ISIS Informatics Ltd), Mr. Paul A Francis, (International CIM Consultants), Mr. Andrew Murison (Bradford Metal Works Ltd), Mr. Adrian Blower and Mr. Gary Smith (DEA UK Ltd), Mr. David Bennett, Mr. Ken Gough and Mr. Clive Rackham (McDonnell Douglas Information Systems Ltd) and others.

Published by CIMware Ltd. UK and CIMware USA, Inc. at http://www.cimwareukandusa.com, © Copyright by CIMware Ltd. UK and CIMware USA, Inc., 1999 - 2000.

If you are a viewer of a legitimate copy of the above video programs on tapes or on CDs, please feel free to view and / or download this workbook, with its full contents, FREE of charge, but always mention the website: http://www.cimwareukandusa.com and the author(s) as the source!

Website: http://www.cimwareukandusa.com

Optional on-line email support: cimware@cimwareukandusa.com

Please use this Workbook together with your Video Tapes or VideoCDs!

This section covers the following:

Tape/Vol. 9: A Summary of CIM Lessons Learned...Tape/Vol. 10: FMS Cell and System Design Rules.

Tape/Vol.

9. Starts Here: A Summary of CIM

Lessons Learned...

As Professor Ranky explains, in this program we discuss the following:

Think of the entire range of small FMCs, as shown below on the video screen print, as well as larger and more complex FMSs, or CIM systems.

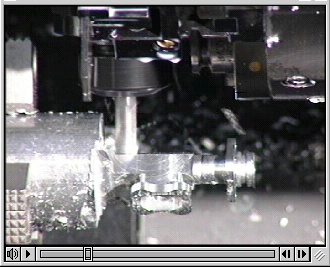

In this image (taken from the original digital video clip) you can see a 4 axis turning cell working on a complex 3D component. The beauty of this Hitachi-Seiki Hicell machine is that it can turn as well as mill, in some cases simultaneously! (The actual video sows the entire process in detail).

As you enter the world of Computer Integrated Manufacturing...You should always ask yourselves: What are the major processes? Why do we have to deal with the selected processes? What are the essential interactions between the processes? Why? What are the "people" issues? Are these critical? What are the technology issues? Which are critical? What benefits will they produce?

Dr. Murison explains the most important steps when starting a cellular manufacturing (FMC), or FMS (Flexible Manufacturing System), or CIM (Computer Integrated Design and Manufacturing) project. He has developed several complex systems, therefore his words should be noted by all of us.

As part of a team, discuss, or if you are studying on your own, think about the following:

This video program discusses the following:

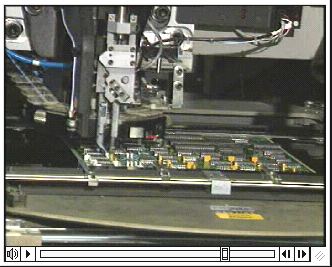

(Note that the principles discussed and the industrial examples shown are applicable to both mechanical as well as electronic manufacturing. The video screen print below illustrates an IC chip / PCB, Printed Circuit Board, assembly process).

In this image (taken from the original digital video clip) you can see an electronic PCB (Printed Circuit Board) assembly process under computer control as part of an electronic assembly/ manufacturing cell. (Courtesy of GPT / Siemens / Plessey, UK). The actual video on the CD shows the entire process in detail. Enjoy it!

Let us consider cell architectures... When analyzing or designing a cell, first think of the processes the cell controller must perform. Then consider the actual conversion process. What does the cell and why?

Think of the processes the cell input / output and the cell buffer must perform.

Discuss manufacturing cell design...

Based on the seen industrial cell / FMS examples discuss manufacturing cell design principles...

Mr. Les Pratt introduces Yamazaki - Mazak industrial examples of cellular manufacture. The actual video illustrates such cells and processes in operation.

Based on the seen industrial examples, as well as what we have discussed in terms of information flow within and outside the cell, discuss manufacturing cell design and operation control aspects.

Focus on the differences between the conventional and the advanced, cellular approach: