Web-based Video Workbook

for

FMS Video Programs Vol. 13 & 14,

on Video Tapes 13 & 14 or on Digital Video CD

by

Written and presented by Dr. Paul G. Ranky and Industrial Contributors, including Mr. Robin Truman (GPT-GEC Plessey Telecommunications Ltd), Mr. Michael J. Legg and Mr. Alan M. Rines (Hitachi Seiki UK Ltd.), Dr. Allan Parker (Lucas Engineering & Systems Ltd), Mr. Roland Thomas and Mr. Wim Onink (ERT Ltd), Mr. Les Pratt (Yamazaki Machinery UK Ltd), Mr. Geoff Harrington (ISIS Informatics Ltd), Mr. Paul A Francis, (International CIM Consultants), Mr. Andrew Murison (Bradford Metal Works Ltd), Mr. Adrian Blower and Mr. Gary Smith (DEA UK Ltd), Mr. David Bennett, Mr. Ken Gough and Mr. Clive Rackham (McDonnell Douglas Information Systems Ltd) and others.

Published by CIMware Ltd. UK and CIMware USA, Inc. at http://www.cimwareukandusa.com, © Copyright by CIMware Ltd. UK and CIMware USA, Inc., 1999 - 2000.

If you are a viewer of a legitimate copy of the above video programs on tapes or on CDs, please feel free to view and / or download this workbook, with its full contents, FREE of charge, but always mention the website: http://www.cimwareukandusa.com and the author(s) as the source!

Website: http://www.cimwareukandusa.com

Optional on-line email support: cimware@cimwareukandusa.com

Please use this Workbook together with your Video Tapes or VideoCDs!

This section covers the following:

Tape/Vol. 13: Design for Manufacture And Assembly (DFM / DFA).Tape/Vol. 14: The Design Aspects of Cells. DFM / DFA and Cell Design Methods.

Tape/Vol. 13. Starts Here: Design for Manufacture And Assembly

In this interactive video program we discuss the following:

As part of a team, discuss, or if you are studying on your own, consider the following:

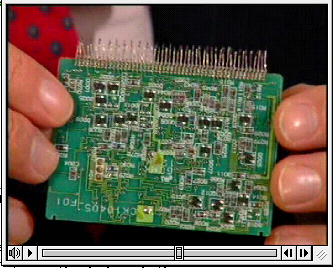

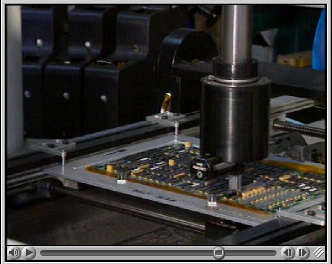

This video screen print illustrates a printed circuit board assembly. The actual video on the CD explains basic Design for Assembly rules, including rules that are applicable to electro-mechanical products.

Based on the illustrated principles and examples of electronic as well as mechanical products, preferably as part of a team, discuss the following:

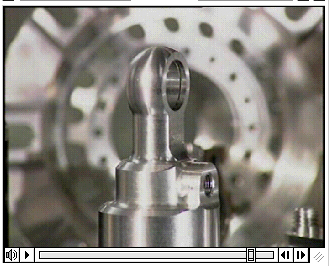

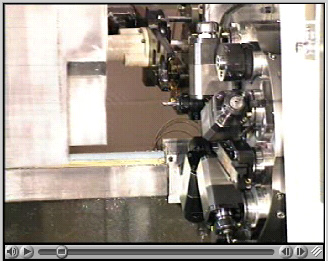

This vido screen print illustrates a complex 3D product manufactured using a four axes controlled Hitachi-Seiki HiCell CNC controlled machine. On the video CD the entire process is illustrated. (Courtesy of Hitachi Seiki Ltd., UK).

In this interactive video program we discuss the following:

In this video clip consider the major system components and integration challenges. (Flexible assembly workstations, cells and lines / systems by Bosch. Courtesy of Bosch GmbH).

In this video clip you can see the entire cycle of a flexible dual robot electronic PCB (Printed Circuit Board) assembly cell by McDonnell Douglas Information Systems. Note the precision control of the robots, and the way parts are identified and located when inserting odd-shaped electronic components onto the board.

Based on the introduced design principles and case studies covering machining, assembly and electronic manufacture, discuss the following:

In this video clip you can see several tools and tool changers, operated under computer control. It should be noted, that tooling is a very significant aspect of the design and the process. Unfortunately many part designers still don't understand or don't want to accept this, despite the fact that tooling costs are often as high as the machines themselves. (Hi Cell machine tool courstey of Hitachi Seiki, Japan)

Discuss manufacturing/assembly cell and system tooling. Why are the following principles and technologies important? How would you design / integrate such systems?

Discuss pallet and part identification. Why is it important to identify pallets and parts in a manufacturing / assembly cell/ assembly system?

In this video clip consider the way parts are identified in a manufacturing cell or system. In the old days shop floor managers were literally "chasing" parts, hence the name: "chasers". Obviously with modern manufacturing and assembly systems under computer control this is neither possible nor feasible anymore. (As an example, consider what happens if the system breaks down... who will find the parts and how? As a system designer how could you prevent such "panic" situations?)

Discuss pallet and part buffering issues in flexible systems...

This video screen print illustrates an automated, robot loaded / unloaded turning cell. Analyse the way the robot loads and unloads parts. Analyse the part variety in th ebuffer area. Are the parts the same? If not how is this possible? (Courtesy of Yamazaki Mazak, UK).

As a summary of this video, review cell design and operation control principles and implementation examples.