Administrative Issues of this Course

What is in my eLearning Pack this Semester?

Detailed Weekly Schedule of the Course

Final Deadline to Submit ALL Assignments

Anonymous Total Quality Feedback Form

This is your latest, therefore the most current schedule. Last update: September 10, 2008 (Update history: August 30, 24, 20, 4, 2008 )

Please Read This! It Contains Vital Information about the Course as well as All the Assignments, Homework and Grades!

PLEASE save the TREES! Please DO NOT Print this syllabus. Use this web site to read it in this electronic format; it will be updated during the semester. Thank you!

The Live, Hybrid and Distance Learning Class (sharing the same syllabus): Total Quality Management within an Analytical Lean Six-sigma Framework

Learn About Total Quality Management, within an Analytical Lean Six-sigma Framework, based on a set of analytical, quantitative, statistical and open-source computational methods and tools. Our purpose is to help you to improve Total Quality in product, process and service system design, explain Process Analytical Technologies (PAT), Good Automated Manufacturing Practices in pharmaceutical, and other manufacturing industries, in IT/ IS, in biomedical engineering, and in various service industries.

In this course we learn analytical methods and tools, and apply them to solve real-world, practical challenges in industry and in R&D. With the aid of advanced 3D interactive multimedia, digital videos, and our analytical tools we go on a virtual tour and analyze various factories, product, process and service systems and industries in the USA, Europe, Japan, China, and around the world, and then apply our quality-focused methods and tools to improve them.

by

Paul G. Ranky, PhD

Full Tenured Professor

Registered Chartered Professional Engineer

Member of the American Society for Quality (ASQ), Audit Division and Lean Enterprise / Advanced Manufacturing Division

Also Member of ISPE, International Society of Pharmaceutical Engineers, USA, ASEE, IEEE, IEE, FEANI, SAE, PMI

Department of Industrial and Manufacturing Engineering and the NJIT IS/ IT Program. NJIT, University Heights, NJ 07102 -1982

More about the Professor’s past and current research work and background at http://www.cimwareukandusa.com/aboutpgr.htm

This course introduces the concept of total quality management, and presents methods, tools, technologies and case studies for product, process and service quality improvement within an extended lean six-sigma quality framework. The emphasis is on prevention through quality engineering, design, and implementation. We go beyond traditional statistical process quality control methods and tools, although we integrate these valuable methods into our framework. We are advocates of feedback-controlled zero defect policies versus random sampling-oriented open-loop quality control. We present practical, as well as research-level cases and challenges focusing on design, manufacturing, real-time systems, supplier and logistics management, project management, quality assurance, process control, construction management, pharmaceutical packaging, automotive assembly, electronic assembly, robotics, and many other cases. We include competitor analysis as appropriate. We learn about advanced process modeling, customer requirements analysis, process risk analysis, various statistical methods, TQM graphical methods, GAMP (Good Automated Manufacturing Processes for the Pharma. industries), Six-sigma, quality auditing processes, lean and green sustainable methods, and an in-depth description of the ISO 9001:2000 international quality standard; a must for quality audits and certifications in most industries. We also learn about web-page design, web-based knowledge documentation, knowledge management, and optionally even video conferencing over the web, when you do your quality audit briefings, etc. on a global basis.

All very new, exciting, and simultaneously analitical as well as practical.

A NEW, and unique feature of this course: International Collaboration between us, and other university students! As part of an informal academic collaborative effort I set up with other universities in Hong Kong/China, Japan, United Kingdom and Europe, we provide here links to international Masters students' work. Please feel free to review, comment, and get involved. This is an attempt to increase the global aspects of this course for the benefit of all students and faculty involved. This link came from Hong Kong MS students, working on an interesting team project (Parking Guidance System PowerPoint Slides). Please let me know if you would like to get in touch with Masters students overseas to work on your assignments together, mimicing a global collaborative effort. This semester we'll focus on lean and sustainable green quality methods.

IE673 is a simultaneously analytical, as well as practical course loaded with useful knowledge, that you can turn into improvement opportunities in almost any factory, institution, or organization, or system. As much as possible, we all try to create a relaxed and happy learning environment in this class, and I try to teach you several new analytical methods and tools, that you can easily deploy in your REAL world, and prosper!

As one of my former students, Major Jack Parker, US Army, National Guard Bureau, Training Division, Washington, DC states about the course:

'As I developed the assignments, I really could have spent the rest of the year going through the principles and methods I learned in this course. Your course materials provided a great education for me in TQM. I look forward to applying my new knowledge in the Army in every means I find possible and feasible. Thanks again for your great instruction and materials.'

Other former students write the following about the course:

=============

Dear Professor Ranky,

Below is the web url where I have posted all my assignments for the

course IEE 655(Concurrent Engineering) & IE 673(TQM).

In addition to the evaluation form i would like to thank you also for

the amount of knowledge you have helped me gain through these courses.

I have been also working at Sanofi Aventis pharma on a Unit Dose

Conversion Project.These principles of CORA, PFRA, Cimpgr model etc

have been of immense help to me for the projects i have been part of

here.The best part is that these tools can be applied in real live

projects.

I am finally graduating this semester and am delighted that thse

methodologies learnt in TQM and CE courses have a real time application

rather than being mere theoretical concepts.

Thank you for all the help Professor.

Wish you a merry christmas and happy new year!!

Thanks !!

Best Regards,

Anup Sudhakaran

Dr Ranky,

Sorry it has taken this long for me to get things wrapped up for the course but all of my struggles are now paying off. I am working at URS Corporation in Paramus NJ in the Paramus Park Mall complex. I am a concrete technician for URS and we oversee all of the concrete work for all of NYC DEP projects.

An example of this is the new water treatment plants that are going to service all of NYC drinking water and all of the miles of piping that go into getting the water there.

The class has been paying off and I find the class to be the best class that I ever took at NJIT. It is extremely rewarding to see in real time all of the management practices that we have learned be put into place.

Thanks you for an eye opening class and I just wish I took it when I was not so stressed out with other things going on around me last semester.

Thanks again for teaching the best class I have ever taken.

Best Regards

Mark A. Bishop

Professor,

Semester is done and I will miss this gorgeous class.

Thanks a lot for your efforts and happy holidays

Happy Learning for REAL

Sincerely

Ahmed Elhenawy

===================

Hello Professor,

My name is Amit Warambhe.Professor i have

submitted all my assignments of TQM-IE 673 course. The course was best

learning experience to get the knowledge of quality aspects and you

shared the course information very well with us through your e-learning

pack.Personally i enjoyed doing the course as i have planned to set-up

a high quality wine industry in INDIA. The quality tools you taught us

and quality management in various industries through your videos in the

class will definately help me to prosper my business.I will definately

need your help in future.Wish you a merry Christmas and have a

prosperous new year.

Thanking You.

Regards.

Amit Warambhe

===================

Prof Ranky

I want to thank you for sharing your incredible knowledge on TQM with

me and the rest of the class. The learning opportunity you provide us

is excellent. Your course materials provided a great education for me.

I admire your way of teaching and most likely I will take the other

course (IE655) you offer.

Thanks for all your help and support.

Regards

Pradip (Peter) Basu

============

Dr. Ranky,

It has been a pleasure working with you, again! The facts that I have picked up throughout the classes you have offered me has enlightened my interest and knowledge in the field.

Thank you for making all this information and knowledge easily accessible.

Yehya Solima

======

I have learned a lot form your courses, and would suggest it to my

friends.

sincerely

Nandeep Nadella

=========

Professor,

This course introduced a new way of viewing processes and procedures in the

workplace and how to recognize breakdowns and failures. Most importantly it

taught me how to approach and improve these processes.

I really enjoyed the course and am sorry to see it end. I will definitely

recommend this course and any other course you teach to fellow students.

Good luck and be well,

Laszlo Herczku

=========

Dear Professor Ranky:

My name is Amanda Mogro, and I am submitting my final assignment for the semester.

Also, I like to express my gratitude to you because this was one of the most interesting classes I had this semester. The case studies were very help and I am sure, I will be using some of the TQM techniques in the future.

Once again thank you,

Sincerely,

Amanda

========

Dear Dr. Paul G. Ranky,

Please see the URL to all my assignments for this course. It was nice

having you with all the great resources in this class.

Regards,

Moses Bernard

=========

Awesome, I really learned a lot of important things applicable in my job.

Thanks,

Fabian Ferreira

Comake Engineer Frozen for Savory Americas

Unilever Foods A2-086A

========

Thanks for a great semester, I enjoyed learning all of these new

concepts!

Thanks,

Mary Petronis

=========

Dear Professor,

I would like to thank you for your efforts in providing one of the best

distance learning courses at NJIT. Like always, I feel very confident

in submitting my coursework.

Best Regards,

Atif Anwar

==========

Hey Professor, It was great working with you, Thank you for sharing all the knowledge.

Pratik Shah

====

Thanks for a good semester, the course was definitely one of the most

interesting and informative courses that I have taken.

Regards,

Steve Karl

=====================

IE673

It's been a great time with you this semester.

You did not teach us TQM, rather you educated us in becoming the very best

that we can ever be. I now look at stuff in a very new and different way. I

gat a new job that I started 3 weeks ago with P & Associates and I did

the interview within the early parts of your class and it helped me a lot. I

got a 3 step promotion and over $20,000 raise compared to my old job.

Prof., you remember saying that you are teaching us to make our desired and

well deserved salaries/wages of $70,000 +? You are so right. Right within the

class, I am pushed into that catergory and it feels great.

THANK YOU SO VERY MUCH PROF.

Thanks once again and have a great holidays. Going diving? or skiing?

Best of luck in all you do.

Your student,

James B. Puplampu

================

Thanks Professor,

A lot of thanks for educating me in TQM(IE673) and CE(IE655). It is very helpful in in my professional development! I was nominated in two categories: “Best Product of the 2006 Year” and “ The Best Team” between all Stryker divisions.

Thanks and regards,

Abram

===============

All in all it was a wonderful experience hope to see you in the Concurrent Engg class this spring semester

Thankyou, Ahsan Ali

===============

Thankyou.

This class was a wonderful experience; you are great, Syed Ali

================

Dear Professor: Thank you so much. This has really been quite an experience and I am now so glad I did go forward with it; the journey was good… Diane Bove

===============

Thanks for your patience. By the way, I've just purchased an Apple iMac and its great!!!! I will never purchase a PC again. Crystal

================

Thank you very much it was a very interesting semester. I have learned a lot in this course. Have a happy and safe holiday. I will see you next semester because I am taking IE655. Brahan Rupan

================

I want to thank you so much for sharing your incredible knowledge of this subject with me and the class. You really made me stretch my capabilities this semester with this class and I have a great sense of accomplishment. So thank you again and I hope you and your family have a great holiday and good luck to you. Thanks again and I hope that the work that I am submitting to you is worth an A, because that would mean a lot come from you. Sincerely, Victor J. McLoughlin

================

It was an amazing course, I found it is very helpful and very interesting.

Unfortunately I am graduated, otherwise I will definitely be in your next

class. Thanks for your help. I have a suggestion about the course though. I just feel the statistical analysis part might can be extended a little bit, maybe it is because I am from math and my major is Stat.:)

Have a nice weekend and a great holiday. Thanks again. Chunsheng Yang

================

Thank you again for a very enlightening semester. Roldan Rivera

===============

Thanks for a great class and semester! Regards, Chad Gassert

===============

Thank you for the great learning opportunity. Olukayode Dada

===============

I would like to tank you very much for a very interesting and

important course. I really feel that I learned many things this

semester. Your approach in teaching and conveying your ideas is very

unique. I did not see this being done in any of my other NJIT

classes. Great job and I look forward to taking more classes with

you. Thank you: Kanar Rabah

===============

I enjoyed your class and I decided to signing up for IE 655 class also.

Regards, Krzysztof Rapciewicz

================

I had a pleasant experience in my career at NJIT. Thanks for all the important and vital things you taught me, while i didn't find them useful in the first class since i had not worked for corporate America I most certainly found them useful now. Respectfully, Francis Garcia

================

Dr. Ranky, Thanks for your patience, and helpful suggestions throughout the semester.

By enrolling in this class and learning the TQM principles proved to be highly

beneficial; learning to build my 1st website was icing on the cake.

I certainly got my money's worth. In fact, I will even go as far as saying

that this class was a bargain. The wealth of knowledge that I now have at my

fingertips from your e-textbook is invaluable. The excel and visio templates

were extra treats that helped facilitate our learning - thanks for your effort

in putting all that material together!

Warmest Regards, See you in IE 655, Bryant R. Jackson - brj2, Electronics Engineer

=================

Thank you for this very nessecary tool to put in our arsenal of

learning. Roldan Rivera

=================

I just wanted to say that this semester has been very useful and that I

have already started to incorporate the lessons learned, in conjunction

with Lean Six Sigma, at my job to evaluate Processes. Hope that you have a wonderful holidays. David Sabanosh

===============

Last but not least let me take this opportunity to thank you for the knowledge you passed on in the classroom and I look forward to applying this knowledge in the real world. Thanks for the learning experience, George Authur

=================

Being in your class was a learning experience, I now look forward to putting the knowledge gain into work practice. Thank you, John K. Wilson Jr.

================

Prof Ranky, I just wanted to thank you for inviting Frank Reick to class last Monday.

His discussions were very enjoyable and his frankness, honesty, and

overall genuine qualities make it obvious why he is successful and why

you have made him a friend. Please pass on my thanks to him...

Regards, Charlie Maraldo

Enjoy some pictures of this enjoyable session we had with Frank: Frank-Reick-Pic1, Frank-Reick-Pic2, Frank-Reick-Pic3

=================

' Dear Professor Ranky, This is Eduardo Canales. I had taken IE_673 last semester with you as part of my master degree in EM. I just want to thank you for such a valuable tool you taught us as it is TQM. Right now, I am working on a matrix evaluation and I remember. I had your Ranky Cora excel tool, which I am using.

The fact that it's in a CD and it's on excel make it practical and fast to use. But not only is the Ranky Cora but all other tools that are in the CD.

Again thanks for your teaching and guidance.

Sincerely, Eduardo

========

Dear Professor Ranky, I would like you know that I truly enjoyed your class yesterday. After graduating from NJIT with a degree in CoE { computer engineering] I was unable to find a job that I liked and would like to make a career in and felt horrible that I went to school for engineering and came out with pretty much nothing. That was when I decided to look for something in the Finance field and fortunately I was able to land a job, and I like dealing with money and control it has on society. Yesterday’s class made me realize why I did engineering and I was good to know that I didn’t lose the love I had for math, science, inventions... just engineering in general.

I am looking forward to class next week!

Regards,

Alka

========

[History: Prof Ranky has invited Frank Rick, an inventor and engineer, and holder of 40 (!) US Patents to talk to our class on innovation and quality issues. Note, that if at all possible, in every semester I try to invite an excellent guest speaker in the program]

... I must say that this class has been very interesting so far and I really enjoyed the speaker last week. Having him come to class and talk about Real Life Experiences is a very rewarding experience that no Professor at NJIT has offered to me during my college experience. I hope we can have a few more?

Thank You

Keith Mueller.

========

Dear professor:

Since I don’t have project management experience, I felt difficult to

get into it in the beginning of this course. After I briefly went

through your eBook, I got some sense. When I read the detail of each

chapter, I found that the course is so practicable, useful and very

attractive. The TQM methods are not just useful in project; they could

be used everywhere, even in living activities. Now I like the course

very much, I believe I have been getting the essence of the course; it

must help me in my career. Thank you very much. I am very appreciated.

Thanks again.

Yours truly,

Haiming Sun.

========

Prof. Ranky,

I've just finished viewing both of the DVD's you provided for the

IE673 class (sorry it took me so long to watch them both) and must

comment about how close they both struck to my own professional

experiences. I currently work as an engineering manager for a lighting

company that does about half of it's North American business in

automotive supplying such items as dome lights, turn signals,

instrument panel lighting, etc to various foreign and domestic

carmakers. About two weeks ago I had the opportunity to visit the BMW

plant in Spartanburg, SC (BMW owns Mini, right?) because of some

components we were supplying to a Tier 1 in the area. What a

tremendous operation! As far as automotive in general, I can say one

thing about...it's tough!

In my former company, I was a Product Development manager for a

precision stamping company. Once used a CMM not unlike the one in the

Mini video (a bit smaller though). That company manufactured a number

of metal shielding components for computers, cell phones and the like.

Interestingly enough, we were working with two big RFID companies,

namely Alien and Matrics (now Symbol) to develop a way to stamp the

RFID antennae instead of chemically etch or conductive print them.

Anyway, wanted to thank you for the opportunity to reminisce about

some of my working experiences.

Wayne

=========

Prof,

Thank you very much. I really enjoyed your class and feel disappointed that it is all almost over...

I have a better idea about TQM and I find myself emphasizing the same in my other management classes , at work, and even with my other outside contacts. It definitely made me think twice before I even react myself to the customers and my fellow workers. I highly appreciate the way you have compiled the study materials.

I am sure I am not the only one who is benefiting from this course. Probably many others. I have even recommended this course to my other class mates.

Thanks for all your help and support.

With Best Regards,

Indira Girija

===================

Hi Prof Ranky

I was wondering since it will be the last class next week... Can we see the other FORD ROUGE video that you shot.

and possible other videos that you have shot ( e learning) similar to that one you showed us last week,

I would enjoy it very much if we could....

Thanks.

===================

Professor Ranky:

I would like to express that I admire your way of teaching. I have to admit that I learn a lot of interesting topics and subjects during the Summer of 2005 through "Cuncureent Engineering" and this Fall through "Total Quality Management", not to mention that I learned how to create the website and post my assignments on it which I had no clue about it before.

The good thing that I can apply use all of what I learned in my work (in small scale) and even in my day life.

So. thank you very much.

Baher Girgis

===========================

Hi Prof. Ranky

Thank You for a really exciting semester. I must say one thing... When I first was going into a masters program I was headed towards Civil Engineering. I am glad I chose Engineering Management. Your class has really opened up doors and ideas for me that I never knew existed.....

I do appreciate and have enjoyed your approach to getting us to learn this material. It has been very enjoyable.

So I thank you

K. Mueller

===========================

I have successfully completed my final semester, with this I complete my

Master's in Engineering Mgmt. and all set for the Graduate walk slated for

May'06.

I will be joining full time with GE as a Project Application Engineer based at

Lombard(IL) by 3rd week of Jan'06. My education and work experience will help

me take up this challenging & exciting position.

It has been a great learning experience for me to be associated with you, It

would not have been possible for me to contribute without your help and

support. I value your contribution in my development as person and

professional. Thank You All.

With Best Wishes & Regards,

Rajesh

===============================

Professor Ranky,

I am excited to be taking your class again. TQM (Spring 05 was

excellent).

David Adwedaa

===============================

Good Evening Professor,

Last semester's class was incredible since it is helping me in different areas of my current job. My Director wants to digitize all the documents in our department. I am trying to convince them to put them on a website that is accessible only to the people that should have access.

I thought of that idea after taking your class! I have thought about many ideas that can be implemented thanks to the new concepts that I learned last semester. It was a very hard class!, but well worth it.

Alexis Rodriguez

=============================

Thank you for the course. I really enjoyed it and learned a lot. The

project was very interessting and challenging too.

Thanks & Regards,

Ashley

=============================

Dear Mr. Ranky.

Thank you for your advice and for this past semester. I hope you liked my

work. The tools you taught us will be really helpful. Hope to keep in touch

and it would be my pleasure if we even do scuba diving together. Thanks

again.

By the way I just received an invitation from GAP headquarters to San

Francisco for a final interview...

Cengiz Dincer

============================

...Interesting class last night. Sorry for butting in maybe a little too

much but I was trying to be helpful - As I am sure Diane was also. I

also feel you need not apologize for your teaching style. Your

experiences are relevant and are appropriate for inclusion in the

discussion.

Charlie Maraldo

===============================

Hope all is well with you, I just wanted to wish you Happy Holidays! I am in California now and will be going tomorrow for a 2-week vacation. I am really enjoying my job at Boeing and I appreciate all the advice you've given us throughout the TQM course. Hope you have a wonderful time!

Warmest Wishes,

Linda

My response to these emails...

I have to admit, that student comments like the ones above make me not just incredibly happy, but also work harder every semester to give you the best and latest, and to continuously update and improve this course and the learning resources. I know it is popular because we all learn useful methods and tools, as well as see the REAL WORLD via virtual factory tours on videos, and then apply the analytical methods; I am delighted, that you like my 3D eBooks and digital videos too!

Note, that this is a combined Welcome Letter and Course Outline for both the live, as well as the distance learning class. Please read it carefully. You will find all essential course information here.

Please note, that this document will be updated during the semester. If anything is unclear please contact me.

Some really useful advice about the style of professional communication...

Often I get some truly friendly emails from my students... many of these include SMS-style text messages, 'buddy language', such as 'Hi Paul, how r you doin...', etc.

Whilst I am flattered by your friendly communication style, there is something I must bring to your attention. At NJIT it is not just my job to teach you analytical skills, but also professional courtesy and conduct so that you become successful in US and international industry.

For communication (emails) in my courses at NJIT you must observe the following:

I hereby kindly inform you that these NJIT guidelines must be met in future electronic communication.

Regards,

Prof. Ranky

P.S.

Had I phrased my emails in a friendly SMS-style, or all in capital letters to my boss during my first job I would have been fired on the spot...

Contact Information...

Mailing Address: Paul G. Ranky, PhD

Full Tenured Professor

Department of Industrial and Manufacturing Engineering and IT

NJIT, University Heights, NJ 07102 -1982

You can email me at NJIT: ranky@njit.edu (Please note, that for reliability reasons I have added another email address: paul.ranky.njit.edu@mac.com. Please use this and send again your email if you don't get an answer from me within 5 to 6 working days. I can read the paul.ranky.njit.edu@mac.com account over the Internet anywhere where I have Internet access, therefore even if I am away at a conference on NJIT business, or research we can be in touch.)

Tel at home (in case of an emergency only, 24 hrs, but preferably during normal hours, 8.00 am to 10.00 pm) you can call me at home: (201) 493 9561

Note, that my office is in ITC 2519 at NJIT.

My office hours for the semester will be on the day the of the live class at 5.30 pm to 6 pm in my office, GITC 2519, and at 9 pm after class (please look up on the NJIT website where the live class is held). Other office hrs. are available unless I am away on official NJIT business. If these are inconvenient hours for you please ask for an appointment by email, and I'll be happy to see you as soon as I can.

Find out more about the Professor’s past and current research work and background at (don't miss some of my best diving and skiing pictures...):

http://www.cimwareukandusa.com/aboutpgr.htm

Some more examples with videos of our related new R&D work we have completed for the LSC (The Liberty Science Center in New Jersey). These are the web sites:

http://njit-lsc.njit.edu/pauldesign.html

and

http://njit-lsc.njit.edu/paulrobot.html

Enjoy!

Academic Calendar

Please look up the NJIT website.

What are Hybrid Courses?

hy·brid - noun - something of mixed origin or composition; something, such as a computer or automobile plant, having two kinds of components that produce the same or similar results.

Hybrid courses (also known as blended or mixed mode courses) are courses in which a significant portion of the learning activities have been moved online and time traditionally spent in the classroom is reduced but not eliminated.

The goal of hybrid courses is to pair the best features of face-to-face teaching with the best options of online learning to promote active and independent learning and reduce class seat time.

Using instructional technologies, the hybrid model forces the redesign of some lecture or lab content into new online learning activities, such as case studies, tutorials, self-testing exercises, simulations, and online group collaborations.

This site (ref.: http://media.njit.edu/hybrid/) was created in support of NJIT's Pilot Program in Hybrid Learning and the Weekend University.

"Within five years, you'll see a very significant number of classes that are available in a hybrid fashion," says John R. Bourne, a professor of electrical and computer engineering at Franklin W. Olin College of Engineering who is editor of the Journal of Asynchronous Learning Networks. "I would guess that somewhere in the 80- to 90-percent range of classes could sometime become hybrid."

And he says he expects to see more students choose to take online courses even if they live on campus.

"Hybrid Teaching Seeks to End the Divide Between Traditional and Online Instruction" by Jeffrey R. Young, March 22, 2002, Chronicle of Higher Education

Ref.: http://media.njit.edu/hybrid/

IMPORTANT NOTES TO ALL STUDENTS :

As an NJIT undergraduate, graduate, live and/ or Distance learning, or in other words eLearning Student, or hybrid course student you are entitled to benefit of significant FREE computing resources, meaning hardware, lots of free software, as well as on-line email, web-site storage space, and related Internet and NJIT intranet server services. The steps below intend to help you on how to set up a web page for documenting your assignments for this course. Please read and follow each step. Obviously if you already have a web page, either through work, or business, or otherwise, please feel free to use that, or the one you prefer. (All we want is for you to learn the method, and then put all your assignments on the web, learn how to manage your knowledge over the web, and then email your URL with your assignments to the instructor for grading). Note, that you can use any suitable web authoring software. NJIT has a few too.

These are the steps to follow (as provided by NJIT's IT and Computing Services):

Hopefully all works... I'd like to see your beautiful webpages!

One of my students offered this explanation on how to upload webpages to the NJIT server: (new version: October 27, 2005 state; might have changed...) Click to see it in .html

Also, another student of mine suggests to use Netscape for free webpage design. This is the link: Netscape 7.2 is free for download for both PC and Mac at the following URL:

http://browser.netscape.com/ns8/download/archive72x.jsp

Last, but not least: ALWAYS test your uploaded assignment using your own, as well as somebody else's computer, to make sure that everything works fine. (Also, ask one of your classmates, or friends to check it for you, by sending him/her an email with a full URL in it, like this: http://www.mycoursewebpage.edu. Always include the full URL into the email, else it won't link directly).

Also note, that besides the class discussions (live class), the eLearning pack eBooks have several examples on the architecture of simple and complex web-pages. All of these are in open source, please study them! (Note, that open-source does not mean that you can upload an entire eBook of mine, or video onto a server on the web. This would be a major copyright violation!!!! Try to stay out of trouble, PLEASE!)

As always,

Happy Learning for REAL,

Professor Paul G Ranky, PhD

Welcome to IE673, one of the most useful TQM courses you’ll ever take! Please read these notes. If anything is unclear please call me or email me. I am here to help you! Prerequisite: instructor’s approval.

Narrative Description of the Course: Total quality management is an approach to business involvement led by the theme of quality. It involves the continual satisfaction of customer requirements at the lowest cost by harnessing the efforts of everybody in the company. Quality assurance means sustaining a system which prevents defects. This includes quality control and quality engineering. Quality control means establishing and maintaining specified quality standards of products / processes / or a service; quality engineering is the establishment and execution of tests to measure product quality and adherence to acceptance criteria.

This course explains the importance of reducing variation for the purpose of implementing total quality in every process of the enterprise. Furthermore, IE673 represents a modular product, process, service design, implementation and management approach to the introduction of various TQM methods, tools, technologies and their management issues within a variety of small, medium and large enterprises.

As often defined "quality is the overall level of product /process / service excellence". It is also quite obvious that without similarly "excellent people, equipment and software" , or in other words, resources, one cannot provide the desired level of quality at the predefined cost. According to Jaguar Cars, "Quality is making money out of satisfying customers. Quality comes first". John F. Akers, former CEO of IBM, defines quality as follows: "Quality is everyone's job. Quality is essential merely to stay in the race". Others claim that: "Quality means putting the customers first every time".

Dr. Akimasa Kurimoto, Yamazaki Machinery (Japan) states that: "The success or failure of the new business strategies is, in general, attributed to the capability of the company to create its culture in ways that would make the new business strategy work. Quality is a fundamental management philosophy, causing cultural change of mind and attitude. Total quality management is the prime corporate business strategy to facilitate the best blend of management and working practice".

Lucas Engineering & Systems (UK and USA), defines Total Quality as follows: "The term Total Quality of Performance relates not just to the technical quality of products but rather to the quality of performance of every function in an organization. This is in recognition of the fact that the quality and cost of a product depend upon its design, the lead times and the reliability of the processes operated by many contributory departments (both manufacturing and administrative), the choice of materials and the effectiveness of supporting structures".

Mike Robson, international (US-based) quality expert, claims that: "We all want quality and excellence. Excellence is a journey, not a destination. There is no magic to quality". The conclusion is that every manufacturing (and other) enterprise needs a Total Quality system which is:

The main problems when applying traditional quality management philosophy include the following:

On the contrary, modern, progressive thinking we follow in this class claims: because Total Quality Management involves every person, aspect and machine (i.e. product, process, control and resource) of the organization, it requires a total commitment. It is not a quick "test and fix" approach. It is a preventive system designed into every aspect of the World Class Design, Manufacturing and Service enterprise, including product design, manufacture, management, administration and others. In accounting terms modern TQM is costing less than conventional quality systems do, because they can and do prevent failures!

In order to learn the above outlined principles, methods, tools and technologies, the course is supported by a comprehensive eLearning package (for both live, hybrid and distance learning students these packs are the same in structure). An eLearning pack typically contains an eTextbook, we call it the 3D eBook on DVD, some printed material, and other web-browser readable, open source 3D interactive multimedia, digital videos and others.

The eLEarning Packs contain real-world research and industrial case studies, as well as open source, professional active code and spreadsheets, that the students can customize when developing their assignments with their own data. (PLease note, that open source does NOT mean, that you can break the copyright law and put an entire 3D eBook CD, or a DVD video on the web !... even if it is going to be on your own server!!!!!) You may of course customize the speardsheets and submit them as your assignments on your webpages with credits given.

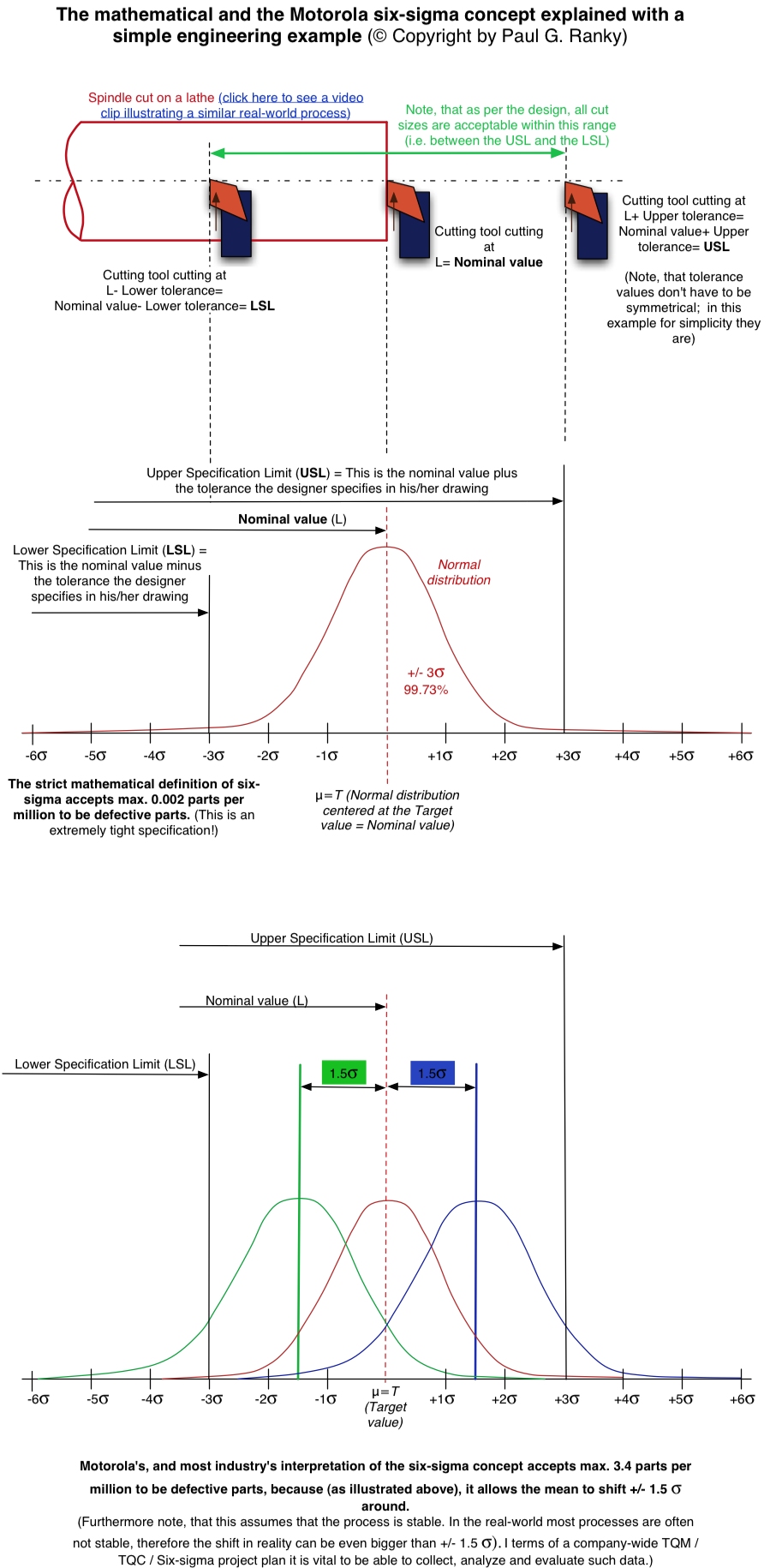

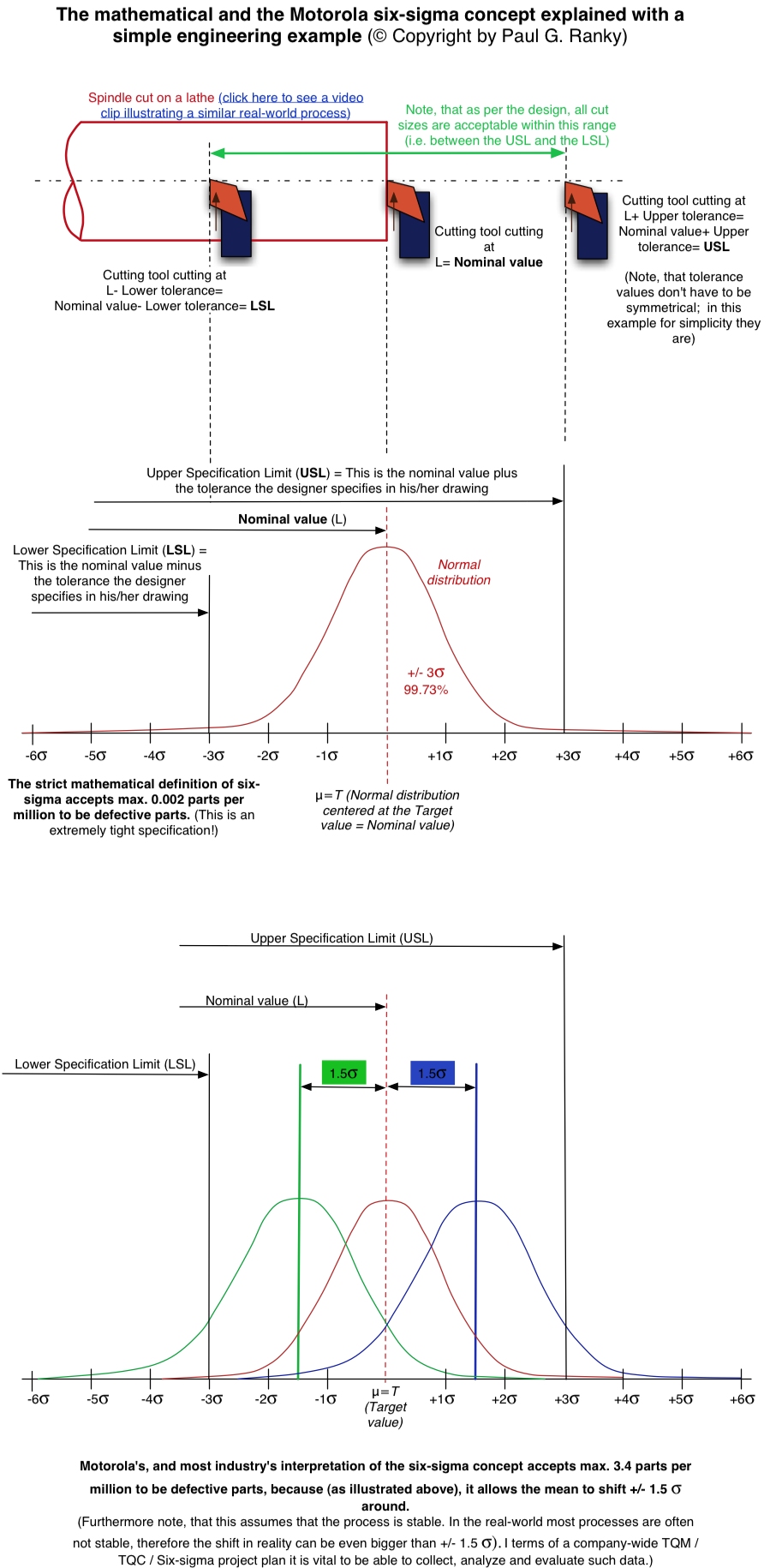

The fundamental goal of TQM and TQC (Total Quality Management and Control) is to program, measure and keep process variability under control. During our studies in this course we discuss several methods, tools and technologies to achieve this goal. One of these methods is identified as six-sigma. In order to give an introductory-level example of our approach, the figure below illustrates the mathematical versus the industrial interpretation of six-sigma. (When reviewing this figure don't forget to play our short sample video, hot-linked to this figure. This is only a short video, because it is run from the server over the Internet. In the eLearning Pack you'll find several resources with video and multimedia content, including 3D videos and animations!)

To summarize, the methods taught in this course are relevant not just to TQM as applied to design, manufacture, test of products, but to a large variety of services too, because they reduce development costs, and improve working capital management, and increase customer satisfaction by offering powerful methods and software tools.

Fundamentally this means waste reduction, therefore lean. If coupled with sustainable green methods, then we can be truly pleased with the results.

Advanced, sustainable green design and manufacturing is used in all areas of manufacturing, including product and process design, control, fabrication, test, assembly, disassembly, and remanufacturing / recycling. In terms of green design and manufacturing sustainability we consider an eco-friendly state, or process that can be maintained over time, for a very long time. Also, the ability of an ecosystem to maintain ecological advanced manufacturing processes and functions, biological diversity, and productivity over time. Furthermore, it encompasses the concept of meeting present manufacturing needs without compromising the ability of future generations to meet their needs. In other words, the characteristic of green, sustainable advanced manufacturing is being able to coexist with another system indefinitely, without either system being damaged. Sustainable green advanced manufacturing concept also emphasizes that the creation of wealth within the community considers the wellbeing of both the human as well as natural environments, and is focused on the more complex processes of development rather than on simple growth or accumulation only.

Upon completing this program of study the candidates will be able to understand and apply TQM Engineering, and related management methods and tools.

Why is the course needed?

There are many methods and solutions to innovate and develop new products and processes, to cut down waste and to improve an organization, a design office, a manufacturing enterprise, a product, or a process. One major discipline is Lean Six-sigma Total Quality Management.

There is no doubt that modern Total Quality Management sounds impressive, but it is also expensive, because it aims at perfection in every aspect of the organization. On the contrary, many large and small companies claim that lean six-sigma total quality is a business strategy. It is "a matter of life or death". According to Harold Geneen, of ITT, USA, "Quality is not only free, it's our most profitable product line".

But how can this be true ? As a simple and quick justification process, think for a moment of the fact that following the traditional quality management philosophy, the fewer the faults, the higher the cost, whereas applying our progressive total quality approach, the fewer the faults, the lower the cost (not to mention the possibility of the cost of a major recall!)

In other words, modern Total Quality Management means:

It is essential to understand that none of the progressive TQM methods we teach in this class work in practice unless they are applied to all levels of the enterprise, including the internal, as well as external supply chains. TQM methods and the quality culture has to be introduced gradually and should be managed by people who understand and support the principles, know how to deal with co-workers, and know the tools. It is a complex process, and a major implementation challenge!

TQM has its best chance if implemented in a modern, digital factory, in which every major process is monitored, based on analytical, quantitative and computational methods... (you can read more on this interesting topic...)

The table below illustrates the way enterprises must develop into international market facing systems, employing knowledgeable and empowered professionals, who are capable of creating and managing new knowledge for the enterprise; exactly the kind of workforce this course is developing.

To summarize, modern TQM addresses the whole enterprise, including products, processes, controls and resources, or in another domain humans and machines, the business systems, product design, process planning, manufacturing planning, the shop floor, packaging, maintenance, and service, including multiple life-cycles, via the internal, as well as the external supply chains.

For Whom is the Course Intended?

I have designed this course for Graduate / Master of Science programs in IE (Industrial Engineering), in EM (Engineering Management), in MnE (Manufacturing Systems Engineering), Pharmaceutical Management, Project Management, as well as an elective course for Graduate Mechanical Engineering, Graduate Computing Science and Graduate Environmental Engineering students. Note, that we follow a modular, object - oriented (OO) approach that makes the topic very adaptable to a variety of different environments. This approach has been successfully tested and run for several years at NJIT as well as on a consulting basis at large companies, such as IBM, Ford Motor Company, Jaguar Cars, GM/EDS, Boeing, Raytheon, and others.

Furthermore, the course is aimed at graduate research students, professional engineers and managers working in industry, wishing to learn about new, TQM methods, tools and technologies and management methods, for the purpose of improving products, processes and services.

Live, Hybrid and Distance Learning Students purchase their educationally priced eLearning Packs from the NJIT Bookstore (pls. contact Frank, or the NJIT Bookstore over the web). PLEASE NOTE, that all of the eLearning Pack materials are copyrighted and therefore are for individual student use only. (As an example, it is illegal for you to purchase the educationally priced package from the NJIT bookstore as an NJIT student, and then send it to your father's business in India for professional / commercial consulting purposes to improve his factory... as it happened in the past...)

On the other hand, you can put selected objects (e.g. images, or video clips, or others up-to-10% of the total content) with proper references to the original material (in the usual format: 'Courtesy of xyz, published by ABC...) into your assignments and post them onto your website, but it is ILLEGAL for you to put an entire eBook (as an example) onto your webpage, or server. I mention this here because some students break the copyright law and therefore can get into major legal trouble with publishers; something I do not want you to experience, because it is expensive and nasty... the USA legal system is one of the best in the world...

Every eLearning Pack architecture is the same, but in terms of actual content is different, because it is customized and updated every semester. This is what you'll find in an eLearning Pack for this course, this semester:

PLEASE note, that all above is for your personal educational non-profit use only, not to be put on the Internet or any servers, or make copies, else you might get into serious trouble with the USA copyright law... THANKS!

The eLearning Packs will give us a great opportunity to work on projects in collaboration with the Four Selected Companies (also in your eLearning Pack). PLEASE NOTE, that each eLearning pack is different, nevertheless the methods we use are the same. Each student should therefore use one eLearning Pack. Also note, that you will need a multimedia PC (approx. 900 MHz, with a CD drive and 800x600 resolution screen min., 1024x768 or better screen preferred), a link to the Internet and email, as well as a recent version (not older than yr. 1998) version of MS-Excel in your machine. PLEASE NOTE, that as a student of NJIT, you are entitled to educational software and hardware discounts, and site licenses, therefore make sure that you take advantage of the huge educational discounts offered (even if you work for a company). (See the NJIT's bookstore, as well as contact NJIT's computing help desks at http://njit.edu for further details).

Reading for a degree... A few words about 'reading for a degree'... for hundreds of years, academics and other professionals all over the world emphasized the importance of reading for a degree. Here is a short list of excellent resources that will help you to deepen your understanding in the subject area of this course. Please read more on the subject if you can:

Schedule: This semester is 15 weeks long. You have to complete and submit 6 assignments (see them below in detail). There is no final examination, the course is assessed based on the 6 assignments. Since each eLearning Pack is different in content, each of you work with me on different assignments, all using the same methods base. The schedule and deadlines for all assignments are below. All assignments should be in electronic format (i.e. email me a full URL within an email). If there is something not clear, please email, or call, or make an appointment and see me.

There is a limited number of rework options (typically one per assignment) to assure that you do your best and learn the most, and of course get the fair grade for your efforts. I am keen to help, but I need your help to be able to help you. Your hard and timely work is the best help for all of us! I follow a fair system; ask my past students...

This is the way the rework of assignments works: you submit your assignment on deadline (or before) and within a few days I'll grade it and email you the grade with comments. Then you can start to improve the assignment based on my comments. After this do not resubmit it, only at the end of semester when all assignments are to be reworked and resubmitted anyway. Then I can reward you (hopefully) for all improvements you have made during the semester on all your assignments. You control your web page, therefore you work on it when you can, as many times as you can. All I need is deadlines to be kept! This is fair and mimics real world behavior.

Class 1/ NJIT Week 1 (Note that class numbers correspond to the semester week numbers at NJIT). Introduction and overview of the course as well as the subject: What is TQM? Why do we need TQM, and what are the main drivers? TQM in a traditional and in a modern design and manufacturing, and service - oriented enterprise. An overview of the course, the eLearning Pack, and student requirements analysis (i.e. what students would like to learn whilst studying in this course). Part 1: TQM in a traditional and in a modern design and manufacturing, and service -oriented enterprise. An overview of US and international TQM standards. TQM process and enterprise models. Engineering management focus on how to find and reduce quality-related waste, and how to create TQM models, that are analytical, quantitative and computational, as well as have a chance of getting implemented in an enterprise. An overview of modern TQM knowledge documentation and knowledge management methods and issues; An overview of the assignments in this course, and a discussion on what the students have to accomplish to pass this course with a high grade.

Student Activities (this is what you should do to get an 'A' in this class, and most importantly learn the subject):

Class 2 / NJIT Week 2 Part 2: TQM in a traditional and in a modern design and manufacturing, and service - oriented enterprise. International TQM standards. An overview of TQM methods, graphical, statistical and simulation tools and some technologies supporting design, manufacturing and service quality. Object - oriented (OO) TQM process and enterprise models are introduced. Engineering management focus on how to find and reduce quality-related waste; and how to create TQM models, that are analytical, quantitative and computational, as well as have a chance of getting implemented in an enterprise. Read Chapters 1 and 2 in the eBook.

Students present their TQM Project Plans:

Assignment 0: Submit by September 12, by email/or better: on the web: Both live and DL students email their assignments to the instructor as a short executive summary describing the way your virtual company (i.e. the 5th company) will collaborate with the 4 companies (to be found in your customized eLearning Pack), and develop TOGETHER a new quality product, process, or service.

Note: Your product / process, or service you plan to develop MUST be TQM-oriented and you have to spell out the TQM aspects clearly! (This is also a good time to start to set up your own webpage... you can use any server you like; NJIT offers you FREE webhosting. You might want to get a pro. service and pay for it, or try something FREE from the web, like www.tripod.com (my students tell me it is OK, I am not sure, I have NOT tested it).

Include your project Title, Author (Your Name and Your PHOTO, your Class code: IE673 live of DL, Date, your eLearning Pack serial number and the collaborative companies you have ( a MUST!). I will respond to this by email, comment and hopefully accept your plans. Note, that in this and other assignments in this course I give you a lot of freedom to innovate. This is why I do not specify every assignment step-by-step in every detail, and treat you as a problem solving machine... I want you to learn to think, act and innovate better and better all the way... I hope you like the idea, because innovation is the ONLY future for us in a global economy... (See our discussions on Globalization in the TQM eBook in detail).

Besides the business plan in this assignment, please see the videos in your eLearning Pack and write a short 200-300 or so long summary on each of them, focusing on TQM aspects: 'What TQM lessons have I learned from each of these videos?

To help you, these are the detailed steps you should take:

Typical Mistakes:

Classes 3, and 4 / NJIT Week 3 and / NJIT Week 4 US and international TQM standards (goals, architecture, pitfalls, practical implementation issues and rules). Object oriented TQM information system models and process modeling (CIMpgr, object oriented TQM process modeling is explained and discussed through exercises and examples). There are some good articles on CIMpgr at ADAM over the web at http://www.cimwareukandusa.com in the ADAM with IT magazine. Read the case study oriented (CIMpgr) articles and see the OO process model examples. (There is a good overview in the 3D eBook, plus there are several templates you can use). You’ll grasp it quickly. You can draw these diagrams with any simple 2D drawing tool, maybe best with VISIO, or CORAL Draw, or PowerPoint, or ADOBE Illustrator, on the PC and OmniGraffle on the Mac in Unix, or others. Please note, that the templates on the eBook CDs are in the latest Visio. Visio is available FREE from the MS website for 1 month, or from NJIT for longer. Read Chapters 3, 4 and 5 in the TQM eBook.

PLEASE do NOT send me Visio source files. Treat me as a global collaborator. I have the web and Excel... and Office... Email me a webpage URL, or in the worst case an MS-Word file with a .jpg image of your models in it, or in PDF.

Submit by September 26 (note, that 'End of Week', for all cases in this course means Friday, 5.00 p.m. of that week)! Assignment No. 1: A TQM Process / System Modeling Method (as Part of the Internal and External Supply Chain) (After having submitted this to me I’ll make comments on it that you suppose to consider and then rework your assignment). (Max. 20%)

Please note, that the best assignments show evidence that the student has worked through the learning material provided on CD-ROMs, web and in the eTextbook. Therefore feel free to incorporate digital images, text and even video clips or 3D VR objects provided on the CDs into your assignment; nevertheless never forget to credit the source of such objects in the bibliography. (Obviously it is illegal for you to put the entire eBook on the web, because that would violate international copyright laws.)

Also note, that as of 2008 this assignment became very important for pharmaceutical engineers and management too. Process modeling was always crucially important in hi-tech industries, such as digital computers, cameras, aerospace, automobiles, etc. The pharma industry has recently realized, that they should catch up and deploy Process Analytical Technologies (PAT). To do this you need advanced process modeling. (This is because of the huge quality improvement, as well as saving opportunities...)

Process analytical technology (PAT) is the wave of the future for the pharmaceutical industry.

As defined by the FDA, PAT is “A system for designing, analyzing, and controlling manufacturing through timely measurements (i.e., during processing) of critical quality and performance attributes of raw and in-process materials and processes with the goal of ensuring final product quality.”

As a scientific, risk-based framework, PAT is intended to support innovation and efficiency in pharmaceutical development, manufacturing, and quality assurance.

The framework is founded on process understanding to facilitate innovation and risk-based regulatory decisions by industry and the Agency.'

The good news, is that in this course we discuss all of these methods, supported by powerful tools, including process modeling with CIMpgr, innovation by means of customer requirements analysis (CORA), risk-based design by means of (PFRA), and process quality improvements by means of statistical methods.

In terms of assignment documentation method, please follow the Appendix of the eTextbook in your Learning Pack.

Please follow this structure for your assignment:

Typical Mistakes: Why am I loosing grade points in this assignment?

Classes 5 and 6 / NJIT Week 5 and 6

QFD (Quality Function Deployment); TQM Requirements Analysis is discussed with 3D Virtual Reality examples as an integrated Total Quality Management methodology. Read Chapters 6, 7 and 8 in the eBook: Intro to TQM eBook. Also watch the Industrial Case Study Videos in your eLearning Pack.

Student Activities:

QFD (Quality Function Deployment) / Requirements analysis is discussed with 3D Virtual Reality examples as a Concurrent Engineering methodology. Focus on the Assignment this week! We like professional quality assignments! Process Improvement and Process Control Analysis, and a Quantitative, Computational Solution: Control Charts for Variables and Attributes. Mathematical modeling with examples. Design of experiments and the extended Ranky/Taguchi method. (You can find this TQM methodology including examples in the TQM eTextbook CD-ROM in your eLearning Pack).

Submit by October 10. Assignment No. 2: QFD (Quality Function Deployment; Component Oriented TQM Process Related Customer Requirements Analysis).

Read the main eTextbook of the course by Ranky, Paul, G.: An Introduction to Total Quality Management & Control and ...

When developing the QFD1 matrix for a TQM product / process, or service try to put down all

Please note, that the best assignments show evidence that the student has worked through the learning material provided in the eLearning Pack, therefore feel free to incorporate digital images, text and even video clips or 3D VR objects provided on the CDs into your assignment; nevertheless never forget to credit the source of such objects in the bibliography.

Typical Mistakes: Why am I loosing grade points in this assignment?

The integration of quality into every process; An overview of TQM methods, graphical and statistical tools. Read Chapters 10 and 11 in the Intro to TQM eBook.

Submit by October 24. Assignment (No.3): Process Improvement and Process Control Analysis, and a Quantitative, Computational Solution: Control Charts for Variables and Attributes (Max. 20%)

Select an area in your company, the 5th company, that needs to be improved by employing Process Control methods. Show how a quantitative, computational solution can help.

Use the Control Charts for Variables and Attributes in our new 'Ranky-Stat_Library' linked to this syllabus below. Simulate and make up the missing input data, if necessary.

As industrial examples, watch the Industrial videos again, as well as study your collaborating 4 companies. Try to identify areas, that are measurable and statistically controllable. Make up missing data; we are keen on learning the methods with realistic data sets!

Read the main eTextbook of the course by Ranky, Paul, G.: An Introduction to Total Quality Management & Control and ... as well as the following (mature beta versions) of Introduction to Statistical Quality Methods and Open Source Tools (please make up missing data for your own case, based on our examples):

Text intro. files to read first (in PDF to assure mathematical accuracy on the web; just click on the filename to download it)

In the textfiles above we compute several examples. These are the active code spreadsheets we have used for organizing our data sets:

This is the template file to be used with your own data: OrgOfData_Templ.xls

These are the actual spreadsheet files we have used to calculate the data in the text files above:

These are the template files to be used with your own data:

Statistical intro. spreadsheets and templates to work with (just click on the filename to download it). Note: for this assignment you need to chose one for Variables, and two control charts for Attributes from the list below:

These are the actual spreadsheet files for control charts for variables:

This is the template file to be used with your own data: ContChartVar_Temp.xls

These are the actual spreadsheet files for control charts for attributes:

pChartConstantSize_testrun.xls

... and the template: pChartConstantSize_templ.xls

... and the template: pChartVartSize_templ.xls

... and the template: cChart_templ.xls

... and the template: uChart_templ.xls

Please note, that all above are still Beta versions... If you find a bug, you'll get extra 10% to your full semester TQM grade! Also, we welcome any suggestions. As an alternative, you can use any pro-tool: such as MINITAB, or others. The benefit of our simple toolset is that you get the source code and see a step-by-step explanation to what our thinking process is... Enjoy!

Typical Mistakes: Why am I loosing grade points in this assignment?

Class 9 / NJIT Week 9 (Please note, that during the Break we don't have a class, nevertheless students are requested to study the identified areas, as described below, using their eLearning Packs).

The Lean Six Sigma Methodology for TQM in Design, Manufacturing, Assembly and Service. An overview of Design For Quality, Assembly, Disassembly, the role of Quality Standards and Quality Circles, and other TQM methods, with 3D Virtual Reality examples and classroom exercises. Read Chapters up to 13 in the Intro to TQM eBook.

JIT and Kanban (Lean) production control methods for design, manufacturing, assembly and service quality Improvement. TQM tools. Networked TQM and TQC in collaborating digital enterprises, and the role of modeling and simulation; Quality leadership, strategic management, and customer satisfaction issues; Globalization, and quality culture issues; Teamwork and how to build great quality teams;

Classes 11 and 12 / NJIT Week 11 and Week 12

The Importance of quality in management, in service industries. Quality communication skills, education, training and TQM knowledge documentation and knowledge management methods and tools; Quality Ethics, TQM culture, benchmarking and globalization; Continuous quality improvement methods and examples.

Based on the Industrial Case Study CD-ROM:

Focus on the TQM engineering related challenges/ questions in this CD. Try to answer 10 selected questions of your choice! Incorporate these answers into the Assignment below!

Submit by November 4. Assignment No. 4: The focus of this assignment is: Process Failure Risk Analysis, as Part of an Industrial TQM Process Improvement Study Based on our PFRA/DFRA (Process Failure Risk / Disassembly Failure Risk Analysis) Method and Tool; meaning the same (Max. 20%) Read Chapter 9 in the Intro to TQM eBook.

For the Industrial Case Study, use the Major Industrial Case study Risk Case Study Videos in your eLearning Pack.

Typical Mistakes: Why am I loosing grade points in this assignment?

Class 13 / NJIT Week 13 (It's almost over... just a few days left...)

TQM audit. Course summary and overview: How the learned methods and tools fit together, and how we can integrate them for specific applications.

Class 14 / NJIT Week 14: TQM Audit and How to Improve a Selected, Industrial System: TQM in a Global, Distributed, Just-in-time, Digital Economy using the learned methods and technologies, including RFID. Read the remaining Chapters in the eBook: Intro to TQM eBook, and watch the RFID Case Study Videos again.

Submit by November 28. Assignment No. 5: TQM Audit and How to Improve a Selected, Industrial System using RFID / TQM methods: TQM in a Global, Distributed, Just-in-time, Digital Economy. Also, write a quality-focused press release to market your company, that has developed the new quality system (Max. 40%). In terms of a guide on how to do this, use the already discussed eight ISO 9001:2000 quality principles.

Class 15: LAST CLASS!!!! Assignment Reviews / Discussions / Optional Presentations for extra credit This Week! We'll discuss any questions you have. I'll spend the entire lecture period helping anyone who needs help. For DL students please join the class if you can, or contact me by email, or phone, or see me in person (please make an appointment in advance via email; thanks).

11.59 pm, December 14, 2008 = ABSOLUTELY THE LAST DAY TO SUBMIT any new or reworked assignments! All submissions MUST be electronic = by email / web.

Schedule and due dates: As above. The total course duration is 15 weeks. Students will be required to complete each assignment. Assignments totaling 110% max. Grade "A" for this class requires min. 90% total. Note, that we don't have a Midterm or a Final exam, because of the integrated nature, the computational requirements, and the research contents of the customized assignments, BUT you must complete Assignments 0, 1 and 2 by around Midterm (see above) if you want to get an 'A', and the rest by the end-of-semester deadline (see above) at a high quality. Thank you for helping me to be able to help you!

IMPORTANT ground rules on improving assignments during semester, and after end the end of semester, after having received your grade:

One more time, the NJIT Grade Scale:

90-100 = A

85-89 = B+

80-84 = B

75-79 = C+

70-74 = C

60-69 = D

0-59 = F

The Results of the Anonymous Total Quality Feedback Form: IE673 (December, 2006)

Laboratory Development Review for Grad. Classes (Ranky, December 2006)

I would like to introduce several laboratory activities to my graduate classes, and therefore I am asking you the following: (Please rate 0 to 10, 10 being the most important / agree, AND please comment if you can! THANKS!)

Q1. Would you like to have our classes in a lab-setting? (i.e. the class and the lab is one integrated whole, as in a studio, with computers, equipment, demos, nice chairs and tables all in one, in a large room)?

100% stated: yes, absolutely no question about that...

Q2: Do you think automated inspection methods and tools are important? (e.g. machine vision, sensors, etc.)

Over 95% stated yes, and rated 10

Q3: Do you think rapid prototyping and rapid manufacturing to achieve quality products and processes is important?

Over 80% stated yes, and rated 10

Q4: Do you think digital design and digital manufacturing (PLM, Product Lifecycle Management) in the TQM context is important?

Over 80% stated yes, and rated 10

Q5: Do you think automation, sensors, robots, in-process inspection to secure zero defect production is important?

Over 95% stated yes, and rated 10

Q6: Do you think medical engineering / pharma. quality process demos are important?

Over 80% stated yes, and rated 10

Q7: Do you think design for quality, design for safety, illustrated with real-world labs. is important?

Over 95% stated yes, and rated 10

Q8: Do you think lean design, manufacture, service, enterprise... is important?

Over 95% stated yes, and rated 10

Informal Quality Feedback Form (Ranky, December, 2006)

Please review the following topics for this class by rating each topic between 0 to 10 (0 = meaning not important / poor quality and 10 = extremely important / excellent!). This feedback form will help your instructor to maximize quality satisfaction.

1. Web-based syllabus (... OK it is long, but is it helpful? Did you read it?):

Over 95% stated yes, and rated 10 ('Typical response: ... it is long, but has all the detail...')

2. eLearning Pack with DVDs and 3D interactive eBooks. (Do you prefer interactive, full color learning resources, or static, black & white traditional printed books?:

100% stated yes, prefer the interactive eBooks versus the traditional printed textbook. Some asked for a printed version too (pls. note, that every eBook can be printed from a browser if you have the money for the ink... some are over 800 pages long...obviously interactive active code, videos, spreadsheet cannot be enjoyed on paper...)

3. Engineering management focus on how to find and reduce quality-related waste:

Over 95% stated yes, and rated 10

4. Object-oriented TQM information system models and process modeling

Over 95% stated yes, and rated 10

5. CORA: QFD (Quality Function Deployment); Requirements Analysis

Over 90% stated yes, and rated 10

6. Process improvement and process control analysis: quantitative methods: control charts for variables and attributes

Over 80% stated yes, and rated 10

7. A real-world challenges and examples on DVDs, based on virtual tours

Over 90% stated yes, and rated 10

8. TQM -oriented risk analysis: PFRA: Process risk analysis

Over 90% stated yes, and rated 10

9. How the learned methods and tools fit together, and how we can integrate them for specific applications

Over 90% stated yes, and rated 10

10. TQM globalization issues

Over 95% stated yes, and rated 10

11. TQM continuous improvement methods and tools illustrated by industrial and R&D case studies

Over 95% stated yes, and rated 10

12. Any other 'Hot TQM / Engineering Management' topics we should cover? Please list and explain.

RFID is a hot topic; also six-sigma challenges in industry; more virtual factory tours on DVD; any realistic issues in the real-world; practical solutions;

=============The Results of the Anonymous Total Quality Feedback Form: IE673 (January 23, 2003) =================

Please rate the following topics planned to be covered in this class by rating each topic between 0 (not important / poor) and 10 (extremely important / excellent!) on the right hand side of the sheet please!

This feedback form will help your instructor to dynamically adjust the breath and the depth of the topics to be covered in this semester in this class to maximize your level of quality satisfaction.

Topics (as per the web-based syllabus) Your rating (0 -> 10)

Web-based syllabus (TQM improvement opportunity: most students haven't seen the syllabus at the time we have started the class... Solution: NJIT should put the live course syllabi (prepared by faculty) with a hot link to the course registration page on the web too... the DL course syllabi are already hotlinked to the web, and this system works reasonably well)

eLearning Pack (Because of the above, the students did not know about the eLearning Packs)

What is TQM? Why do we need TQM, and what are the main drivers? TQM in a traditional and in a modern design and manufacturing, and service -oriented enterprise. (Rated: Very High)

TQM in a traditional and in a modern design and manufacturing, and service -oriented enterprise. (Rated: Very High).

An overview of US and international TQM standards (Rated: High).

TQM process and enterprise models. (Rated: High).

Engineering management focus on how to find and reduce quality-related waste, and how to create TQM models, that are analytical, quantitative and computational, as well as have a chance of getting implemented in an enterprise. (Rated: Very High).

An overview of modern TQM knowledge documentation and knowledge management methods and issues. (Rated: Medium)

An overview of the assignments in this course, and a discussion on what the students have to accomplish to pass this course with a high grade. (Rated: Medium).

Object oriented TQM information system models and process modeling. (Rated: Medium)

QFD (Quality Function Deployment); TQM Requirements Analysis is discussed with 3D Virtual Reality examples as an integrated Total Quality Management methodology. (Rated: High).

Process Improvement and Process Control Analysis, and a Quantitative, Computational Solution: Control Charts for Variables and Attributes. Mathematical modeling with examples. (Rated: High).

The Lean Six Sigma Methodology for TQM in Design, Manufacturing, Assembly and Service. (Rated: High).

The Five 'S's explained with examples (i.e. Sort, Set, Shine, Standardize, Sustain). (Rated: High).

An overview of Design For Quality, Assembly, Disassembly, KANRI, KAISEN, MUDA, MURA, MURI, POKA-YOKE. (Rated: Medium; nevertheless many students did not know what this meant, so we'll discuss these methods)

The role of Quality Standards and Quality Circles. (Rated: High)

A real-world TQM challenge, based on a virtual tour of an existing facility. (Rated: High)

JIT and Kanban (Lean) production control methods for design, manufacturing, assembly and service quality Improvement. (Rated: High)

TQM tools. (Rated: Very High)

How the learned methods and tools fit together, and how we can integrate them for specific applications. (Rated: Very High)

TQM team management methods and issues. TQM in the automotive, aerospace, food, service, medical, and other TQM standards re-visited. (Rated: High).

Quality ethics. Enterprise -wide quality leadership, implementation and management methods. (Rated: Very High).

Globalization issues. (Rated: Medium)

TQM cultural issues; Conflict in the workplace, and how TQM methods and principles can help to avoid them. (Rated: High)

Continuous improvement methods and cases. (Rated: Very High)

TQM project presentation skills. (Rated: High).

Industrial and R&D Case studies for every topic (as listed above). (Two groups have emerged: one rated Very High, the other one Medium)

Any other topic you would like to cover? Please explain. (Received none, meaning, that the class is happy with the offered topics)

It is over! Congratulations! You can now analyze and improve many products and services!

PLEASE save the TREES! Please DO NOT Print this syllabus. Use this web site to read it in this electronic format; it will be updated during the semester. Thank you!